A comprehensive evaluation of infant nourishment products was conducted, encompassing forty-one distinct formulations. This process involved rigorous scientific analysis to assess nutritional content, safety parameters, and overall suitability for infant consumption. Data collected provides a basis for informed recommendations and identifies potential areas for product improvement.

The significance of this evaluation lies in its contribution to safeguarding infant health. By scrutinizing these products against established quality standards and nutritional guidelines, potential risks are minimized, and optimal growth and development are supported. Historically, such testing has been instrumental in shaping regulatory policies and driving manufacturers towards higher levels of safety and product efficacy.

The findings from this assessment form the foundation for subsequent discussions on the specific characteristics of the formulas examined, the methodologies employed, and the implications for both consumers and manufacturers within the infant formula industry.

Guidance Derived from Infant Formula Assessments

The rigorous examination of forty-one infant formula products yielded valuable insights that can inform selection and usage practices. The following guidance is intended to promote safe and effective infant feeding.

Tip 1: Prioritize Nutritional Completeness: Scrutinize the product label to ensure it provides the essential vitamins, minerals, and macronutrients recommended for infant development, aligning with established dietary guidelines.

Tip 2: Verify Ingredient Transparency: A clear and comprehensive list of ingredients allows for informed decisions, particularly for infants with known allergies or sensitivities. Avoid products with vague or unspecified components.

Tip 3: Assess Manufacturing Standards: Confirm that the formula is produced in facilities adhering to stringent quality control measures and regulatory oversight, minimizing the risk of contamination or substandard production.

Tip 4: Evaluate Mixability and Consistency: Proper formula preparation is critical. Look for formulas that dissolve readily in water, minimizing clumping and ensuring consistent nutrient delivery.

Tip 5: Consult with Pediatric Professionals: Individual infant needs vary. Seek guidance from a pediatrician or registered dietitian to determine the most appropriate formula based on the infant’s specific health status and developmental stage.

Tip 6: Monitor Infant Tolerance: Observe the infant for signs of intolerance, such as excessive gas, diarrhea, or skin rashes. Any adverse reactions should be promptly reported to a healthcare provider.

Adhering to these recommendations, derived from comprehensive product evaluations, can contribute to the safe and effective nourishment of infants, promoting optimal health and development.

The subsequent sections of this article will delve into specific aspects of infant formula composition and preparation, providing further context for informed decision-making.

1. Nutritional Completeness

The assessment of nutritional completeness is paramount when evaluating infant formula. The investigation of forty-one distinct baby formulas involved a meticulous examination of their constituent nutrients to ascertain adherence to established guidelines for infant health.

- Macronutrient Profile Adequacy

This facet concerns the evaluation of protein, fat, and carbohydrate content. Insufficient or disproportionate levels of these macronutrients can hinder growth and development. The testing of forty-one baby formulas involved quantifying these components and comparing them against recommended intake levels for infants of various age groups. For example, deviations from established protein-to-fat ratios were flagged for further scrutiny, potentially indicating suboptimal formulation.

- Micronutrient Sufficiency

Micronutrients, including vitamins and minerals, play crucial roles in numerous physiological processes. The assessment of the forty-one formulas included quantifying levels of vitamins A, D, E, K, C, B vitamins, as well as minerals like iron, calcium, zinc, and iodine. Deficiencies in any of these micronutrients can lead to significant health problems. Testing identified formulas with levels falling below recommended thresholds, highlighting potential concerns regarding their long-term use as a sole source of nutrition.

- Amino Acid Composition

The protein component of infant formula must contain an adequate supply of essential amino acids. These amino acids cannot be synthesized by the infant and must be obtained from the diet. Testing the forty-one formulas involved analyzing their amino acid profiles to ensure they meet the specific requirements for infant growth and development. Formulations deficient in key amino acids, such as tryptophan or lysine, would be deemed nutritionally incomplete.

- Fatty Acid Profile Appropriateness

The type and proportion of fatty acids in infant formula influence brain development and immune function. The assessment of the forty-one formulas included analyzing the levels of essential fatty acids, such as omega-3 and omega-6 fatty acids. Furthermore, the presence of trans fats or excessive levels of saturated fats was investigated. Formulations with unbalanced fatty acid profiles or containing detrimental fats were flagged as potentially suboptimal.

The comprehensive evaluation of macronutrient profiles, micronutrient sufficiency, amino acid composition, and fatty acid profile appropriateness provided a robust assessment of the nutritional completeness of the tested infant formulas. The data obtained from these tests allowed for the identification of formulas that met or failed to meet established nutritional guidelines, thereby informing recommendations and promoting infant health.

2. Safety Thresholds

Evaluation of safety thresholds is an integral part of infant formula assessment. The examination of forty-one individual products involved stringent testing to ensure compliance with established safety limits for various contaminants and potentially harmful substances. This process is crucial for safeguarding infant health and preventing adverse reactions.

- Heavy Metal Contamination

Infant formulas must be tested for the presence of heavy metals such as lead, arsenic, cadmium, and mercury. These elements, even in trace amounts, can be neurotoxic and harmful to developing infants. The testing of the forty-one formulas included rigorous analysis to detect and quantify any heavy metal contamination, comparing the findings to established regulatory limits. Any product exceeding these limits would be deemed unsafe for consumption.

- Microbial Pathogens

The presence of microbial pathogens, such as Salmonella, Cronobacter, and E. coli, poses a significant risk to infant health. The forty-one formulas underwent extensive microbiological testing to ensure the absence of these harmful organisms. Sterility testing and analysis for bacterial endotoxins were conducted to verify product safety and minimize the risk of infection in vulnerable infants. Confirmation of pathogenic presence would result in immediate rejection of the product.

- Pesticide Residues

Pesticide residues from agricultural sources can contaminate the raw materials used in infant formula production. The testing of the forty-one products included screening for a wide range of pesticides to ensure that residue levels are below acceptable limits. Gas chromatography-mass spectrometry was employed to detect and quantify pesticide residues, providing assurance that the products comply with established safety standards.

- Plasticizers and Chemical Migration

Plasticizers, such as phthalates and bisphenol A (BPA), can migrate from packaging materials into infant formula, potentially disrupting endocrine function. The forty-one formulas were analyzed for the presence of these chemicals to ensure that migration levels are below established safety thresholds. Liquid chromatography-mass spectrometry was used to detect and quantify plasticizers, mitigating the risk of exposure to harmful chemicals.

These aspects of safety threshold testing, applied to the forty-one infant formula products, demonstrate the comprehensive approach taken to ensure product safety. By rigorously evaluating these parameters, potential risks are minimized, and consumers can be confident in the safety of the formulas they choose for their infants.

3. Ingredient Integrity

Ingredient integrity is a cornerstone of infant formula quality. The assessment of ingredient integrity during the testing of forty-one baby formulas involved verifying the accuracy of ingredient labeling, confirming the absence of undeclared substances, and assessing the quality of individual components. This process is essential for ensuring consumer trust and safeguarding infant health.

- Label Accuracy Verification

This facet involves comparing the declared ingredients on the product label with the actual composition of the formula. Testing included quantitative analysis of macronutrients (proteins, fats, carbohydrates), micronutrients (vitamins, minerals), and other listed ingredients to ensure that their concentrations fall within acceptable ranges of the declared values. Discrepancies between the label and the actual composition could indicate misrepresentation or substandard manufacturing practices and were closely scrutinized in the tested formulas.

- Absence of Undeclared Ingredients

The investigation extended beyond verifying declared ingredients to include screening for undeclared or adulterated substances. Testing methods such as gas chromatography-mass spectrometry (GC-MS) and liquid chromatography-mass spectrometry (LC-MS) were employed to identify any unexpected compounds, including contaminants, unauthorized additives, or substitute ingredients not listed on the label. This is particularly important to detect potentially allergenic substances or harmful additives that could negatively impact infant health. The forty-one formulas were screened against a comprehensive database of known adulterants.

- Source and Quality Assessment of Individual Components

The integrity of individual ingredients also depends on their source and quality. Where feasible, the sourcing of key ingredients was investigated to determine their origin and manufacturing processes. Certificates of analysis and quality control records were reviewed to verify that individual components met established standards for purity, potency, and absence of contaminants. For example, the source of whey protein concentrate was evaluated for its manufacturing processes and potential for residual lactose content. This information supports the overall assessment of formula quality and reliability.

- Assessment of Ingredient Stability

Ingredient stability is crucial for ensuring that the nutritional value of the formula remains consistent throughout its shelf life. The testing of the forty-one formulas included subjecting samples to accelerated storage conditions and evaluating the degradation of key nutrients, such as vitamins and essential fatty acids. Changes in nutrient levels over time were monitored to determine the shelf-life stability of the products and ensure that they meet label claims until the expiration date. Loss of vitamin potency or changes in fatty acid profiles were documented and evaluated.

The rigorous evaluation of these aspects of ingredient integrity, conducted during the testing of the forty-one baby formulas, provides a comprehensive understanding of product quality and reliability. The data obtained informs recommendations and contributes to ensuring that infants receive safe and nutritionally adequate nourishment.

4. Manufacturing Standards

Stringent manufacturing standards are paramount in the production of infant formula. The testing of forty-one baby formulas underscores the critical role these standards play in ensuring product safety, nutritional integrity, and overall quality, thereby protecting the health of vulnerable infants.

- Quality Control Systems

Effective quality control systems are essential at every stage of the manufacturing process, from raw material sourcing to final product packaging. These systems encompass procedures for monitoring critical control points, conducting regular inspections, and implementing corrective actions when deviations occur. For example, in the production of the tested forty-one baby formulas, adherence to Hazard Analysis and Critical Control Points (HACCP) principles was a key indicator of robust quality control. Facilities lacking verifiable HACCP plans or demonstrating inconsistent implementation were flagged for potential concerns.

- Facility Hygiene and Sanitation

Maintaining a high level of hygiene and sanitation in manufacturing facilities is crucial to prevent contamination of infant formula. This includes strict protocols for cleaning and sanitizing equipment, controlling air quality, and managing personnel hygiene. During the evaluation of the forty-one formulas, inspections of manufacturing facilities focused on evidence of effective cleaning practices, proper ventilation systems, and adherence to Good Manufacturing Practices (GMP) regarding personnel attire and hygiene. Facilities with inadequate sanitation practices posed a greater risk of microbial contamination, leading to product recalls and potential harm to infants.

- Process Validation and Control

Process validation ensures that manufacturing processes consistently produce infant formula that meets established quality standards. This involves demonstrating that critical process parameters, such as temperature, pressure, and mixing times, are consistently controlled and monitored. During the testing of the forty-one formulas, documentation of process validation studies was examined to verify that manufacturing processes were adequately controlled. Lack of proper validation increased the risk of inconsistencies in nutrient levels, ingredient mixing, and product sterilization, potentially compromising infant health.

- Traceability and Recall Systems

Robust traceability systems are essential for tracking raw materials, intermediate products, and finished goods throughout the manufacturing process. This enables manufacturers to quickly identify and isolate affected products in the event of a safety concern or product recall. The ability to trace raw materials back to their origin was a key factor in assessing the effectiveness of recall systems during the evaluation of the forty-one baby formulas. Manufacturers with inadequate traceability systems faced greater challenges in responding to potential safety issues, increasing the risk of widespread contamination or harm to infants.

In summary, adherence to stringent manufacturing standards is a critical determinant of infant formula quality and safety. The testing of the forty-one baby formulas highlighted the importance of robust quality control systems, facility hygiene, process validation, and traceability in ensuring that infants receive safe and nutritionally adequate nourishment. Facilities falling short in these areas posed a greater risk to infant health, underscoring the need for rigorous regulatory oversight and continuous improvement in manufacturing practices.

5. Regulatory Compliance

Regulatory compliance serves as the cornerstone for ensuring the safety and nutritional adequacy of infant formula products. The comprehensive testing of forty-one baby formulas was conducted with the explicit purpose of assessing adherence to these mandates, validating claims, and protecting the health of the most vulnerable consumers.

- Adherence to Nutritional Standards

Infant formula regulations, often dictated by bodies such as the FDA in the United States or equivalent agencies internationally, prescribe specific nutrient levels that formulas must meet. Testing the forty-one baby formulas involved meticulous analysis to confirm that protein, fat, carbohydrate, vitamin, and mineral content aligned with these mandated minimum and maximum thresholds. Failure to comply with these standards can result in misbranding, product recalls, and potential harm to infant development. For example, regulations might specify a minimum iron content to prevent anemia, and the testing process rigorously verifies that this requirement is met.

- Absence of Prohibited Substances

Regulatory frameworks prohibit the inclusion of certain substances in infant formula due to potential health risks. The testing of the forty-one formulas involved screening for these prohibited compounds, which may include pesticides, heavy metals, or industrial chemicals exceeding permitted levels. Compliance necessitates demonstrating that the formulas are free from these contaminants, safeguarding infants from potential toxicity. An example would be monitoring for melamine contamination, which has historically posed a significant safety concern in the food industry.

- Accurate Labeling Requirements

Regulations mandate that infant formula labels provide accurate and comprehensive information to consumers. This includes clear statements of ingredients, nutrient content, preparation instructions, and potential allergen warnings. The testing process for the forty-one formulas included verifying that label claims were substantiated by analytical results and that all required information was present and readily understandable. Misleading or inaccurate labeling can compromise consumer safety and lead to improper formula preparation, potentially causing nutritional deficiencies or allergic reactions.

- Manufacturing and Quality Control Standards

Regulatory bodies establish manufacturing and quality control standards to ensure that infant formula is produced under sanitary conditions and with consistent quality. Compliance involves adhering to Good Manufacturing Practices (GMP) and implementing robust quality control procedures throughout the production process. The testing of the forty-one formulas, when relevant, involved auditing manufacturing facilities and reviewing quality control records to assess compliance with these standards. Deficiencies in manufacturing practices can lead to contamination, inconsistent nutrient levels, and compromised product safety.

In summary, the rigorous testing of the forty-one baby formulas was fundamentally driven by the need to ensure comprehensive regulatory compliance. Adherence to these regulations serves as the primary safeguard for infant health, validating product claims, preventing exposure to harmful substances, and ensuring that consumers receive accurate and reliable information. The results of such testing directly inform regulatory actions and contribute to the continuous improvement of infant formula safety and quality standards.

Frequently Asked Questions Regarding Infant Formula Evaluations

The following questions address common inquiries concerning comprehensive infant formula analyses and their implications for consumer understanding.

Question 1: What specific parameters are evaluated during infant formula testing?

Infant formula testing encompasses a wide range of parameters, including but not limited to: nutritional content (macronutrients, micronutrients), heavy metal presence (lead, arsenic, cadmium, mercury), microbial contamination (bacteria, pathogens), pesticide residues, plasticizer migration, ingredient integrity, and label accuracy.

Question 2: How does infant formula testing contribute to infant health?

Rigorous infant formula testing identifies potential nutritional deficiencies, toxic contaminants, and manufacturing deficiencies. These findings provide valuable information for regulatory agencies to establish safety standards and guidelines, protecting infants from potential health risks.

Question 3: What actions are taken if an infant formula fails to meet safety standards?

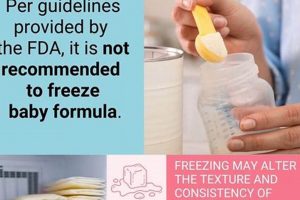

If testing reveals that an infant formula fails to meet established safety standards, the regulatory agency (e.g., FDA) takes appropriate action, which may include issuing a warning, initiating a product recall, or implementing corrective measures to ensure compliance.

Question 4: Can the results of infant formula testing be used to compare different brands?

While testing data can provide insights into the composition and quality of different formulas, it is essential to consult with a healthcare professional to determine the most appropriate formula for a specific infant’s individual needs and circumstances.

Question 5: How often is infant formula testing conducted?

The frequency of infant formula testing can vary depending on regulatory requirements, manufacturer quality control programs, and emerging safety concerns. Ongoing surveillance and periodic testing are essential for ensuring continued compliance and protecting infant health.

Question 6: Who conducts infant formula testing?

Infant formula testing is typically conducted by independent laboratories, regulatory agencies, and manufacturers as part of their quality control programs. These entities employ standardized testing methods and adhere to strict protocols to ensure accurate and reliable results.

In summary, thorough analysis of infant formulas safeguards the well-being of infants by verifying conformity with safety criteria and nutrient requirements.

The discussion will now move toward considerations of costs and benefits from infant formula product evaluations.

Concluding Remarks on Infant Formula Evaluation

The rigorous assessment focused on forty-one infant formula products underscored the complexities inherent in ensuring product safety and nutritional adequacy. Key areas of scrutiny encompassed nutritional completeness, safety thresholds, ingredient integrity, manufacturing standards, and regulatory compliance. The findings highlight the critical importance of comprehensive testing protocols and stringent regulatory oversight in safeguarding infant health.

The data derived from the examination of these formulas emphasize the need for continued vigilance and proactive measures within the infant formula industry. Future efforts should prioritize enhancing testing methodologies, strengthening regulatory frameworks, and fostering transparent communication with consumers to promote informed decision-making and optimize infant well-being. Further research and commitment to product quality remain essential.