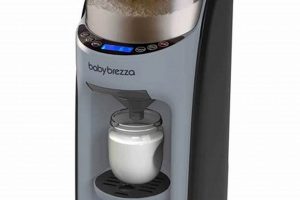

Components designed for the Baby Brezza Formula Pro Advanced represent the physical elements essential for the machine’s proper function. These include items such as the powder container, water tank, mixing funnel, and other detachable pieces integral to the automated formula preparation process. Proper maintenance and replacement of these items are necessary for the device to consistently deliver correctly mixed formula.

The integrity of these components directly impacts the safety and accuracy of formula preparation. Regular cleaning and timely replacement, when necessary, are important to prevent bacterial contamination and ensure consistent formula concentration. Their availability and proper functioning contribute significantly to the convenience and reliability that users expect from the appliance. Historically, the evolution of such devices has focused on simplifying the formula preparation process while maintaining hygiene and accuracy standards.

A closer examination of the specific components, their maintenance requirements, potential issues, and solutions, alongside information on sourcing replacements, will provide a complete understanding of how to maintain the Baby Brezza Formula Pro Advanced for optimal performance.

Maintenance Strategies for Baby Brezza Formula Pro Components

The following outlines essential strategies for maintaining the Baby Brezza Formula Pro Advanced to ensure optimal performance and longevity.

Tip 1: Regular Cleaning is Essential: Implement a consistent cleaning schedule for all detachable parts, following the manufacturer’s guidelines. Residual formula buildup can compromise hygiene and functionality.

Tip 2: Water Tank Hygiene Matters: Empty and thoroughly clean the water tank daily. This prevents the growth of bacteria and mold, ensuring a safe water supply for formula preparation.

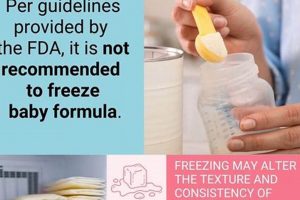

Tip 3: Monitor Powder Container Humidity: Ensure the formula powder container remains dry and airtight. Moisture can lead to clumping and inaccurate dispensing, affecting formula concentration.

Tip 4: Inspect and Replace the Mixing Funnel: The mixing funnel is a critical component. Regularly inspect it for cracks or damage and replace it as recommended to maintain accurate formula mixing.

Tip 5: Calibrate Periodically: Follow the manufacturer’s instructions for calibrating the machine. This ensures accurate dispensing of formula powder and water, contributing to consistent formula preparation.

Tip 6: Descale Regularly: Mineral buildup can affect the machine’s performance. Descale the Baby Brezza Formula Pro Advanced periodically, according to the manufacturer’s recommendations.

Proper maintenance of the Baby Brezza Formula Pro Advanced through diligent cleaning, inspection, and timely replacement of parts ensures its consistent operation, reliable formula preparation, and overall hygiene.

Adhering to these maintenance tips prolongs the device’s lifespan and contributes to the safe and efficient preparation of infant formula.

1. Disassembly Procedure

The disassembly procedure for Baby Brezza Formula Pro Advanced components is intrinsically linked to their effective maintenance and sanitization. The inability to properly disassemble these parts hinders thorough cleaning, creating potential breeding grounds for bacteria. This, in turn, may compromise the safety and hygiene of the prepared formula. For example, residual formula can accumulate in areas inaccessible without complete disassembly, promoting microbial growth that could lead to infant illness. Therefore, a clear and concise disassembly procedure is not merely a convenience; it is a necessity for ensuring the safe operation of the device.

Understanding the correct disassembly procedure enables users to access and clean all surfaces of components such as the mixing funnel, powder container, and water tank. Without this knowledge, users may inadvertently damage parts during attempted cleaning or neglect areas prone to buildup. The manufacturer’s guidelines typically outline the correct sequence for disassembly, specifying necessary tools or techniques. Deviation from these guidelines can result in broken parts, voiding warranties and increasing the risk of improper formula preparation due to damaged components.

The significance of a well-defined disassembly procedure lies in its direct impact on hygiene and machine longevity. When users can easily disassemble, clean, and reassemble the Baby Brezza Formula Pro Advanced components, they are more likely to maintain the device properly. This proactive approach minimizes the risk of bacterial contamination and ensures consistent formula preparation, aligning with the core function and purpose of the device. Furthermore, following the correct disassembly procedure prevents damage, extending the lifespan of these integral components.

2. Cleaning Frequency

Maintaining an appropriate cleaning frequency for components of the Baby Brezza Formula Pro Advanced is paramount to ensuring the safety and effectiveness of the formula preparation process. Inadequate cleaning practices can lead to bacterial contamination and compromised performance of the device, thus directly affecting infant health.

- Powder Container Cleaning

The powder container requires frequent cleaning to prevent clumping and bacterial growth due to formula residue. A daily wipe-down with a dry cloth is recommended to remove any powder accumulation. Monthly deep cleaning with warm, soapy water and thorough drying is essential to eliminate potential contaminants that could compromise the formula’s integrity.

- Water Tank Sanitation

The water tank is susceptible to mineral buildup and bacterial growth. Daily emptying and rinsing of the tank is necessary. Weekly sanitization with a diluted vinegar solution or a manufacturer-recommended cleaning agent helps prevent the formation of biofilms and ensures the water used for formula preparation is free from harmful microorganisms. Failure to maintain proper water tank hygiene can introduce contaminants into the formula.

- Mixing Funnel Hygiene

The mixing funnel, due to its direct contact with both water and formula powder, requires cleaning after every four uses, or at least daily. This component is prone to residue buildup that can impede proper mixing and harbor bacteria. Thorough rinsing and drying are crucial. Periodic sanitization is also recommended to prevent the accumulation of persistent contaminants.

- Air Duct Maintenance

Although less frequently addressed, the air duct system responsible for powder dispensing should be periodically inspected and cleaned. Dust and formula particles can accumulate in the duct, affecting the accuracy of the dispensing mechanism. Monthly vacuuming or gentle cleaning with a soft brush can help maintain the integrity of this crucial component.

These facets of cleaning frequency underscore the need for meticulous maintenance of the Baby Brezza Formula Pro Advanced. Neglecting any of these areas can undermine the intended convenience and safety of the device, potentially exposing infants to health risks. Consistent adherence to the recommended cleaning schedule is crucial for safeguarding the well-being of the child and preserving the functionality of the appliance.

3. Material Composition

The material composition of Baby Brezza Formula Pro Advanced components directly influences their durability, safety, and suitability for contact with infant formula. Different materials exhibit varying degrees of resistance to heat, chemicals, and physical stress, which affects the longevity and hygienic properties of each part. The selection of appropriate materials is not arbitrary; it is a critical design consideration to ensure the machine functions reliably and does not introduce harmful substances into the formula.

For example, the water tank commonly utilizes BPA-free Tritan plastic due to its clarity, impact resistance, and ability to withstand repeated exposure to hot water without leaching chemicals. The mixing funnel, often made from polypropylene, is chosen for its chemical inertness and heat resistance, as it frequently comes into contact with both formula powder and heated water. The powder container, typically constructed from a durable, food-grade plastic, must effectively maintain an airtight seal to prevent moisture intrusion and formula degradation. A failure to use appropriate, food-safe materials can result in the release of harmful chemicals into the prepared formula, posing a significant health risk to the infant. Furthermore, the material composition influences the ease of cleaning and sanitization; materials with smooth, non-porous surfaces are preferable as they minimize bacterial adhesion and facilitate effective cleaning.

Understanding the material composition of each Baby Brezza Formula Pro Advanced component is vital for informed maintenance and replacement decisions. It allows users to select appropriate cleaning agents and methods, preventing damage or degradation of the parts. Furthermore, it enables users to identify potential issues early on, such as discoloration or cracking, which may indicate material fatigue or chemical incompatibility. The proper functioning of this appliance hinges on the integrity of its individual components, and the material composition is a key determinant of that integrity.

4. Replacement Schedule

The replacement schedule for Baby Brezza Formula Pro Advanced components is a critical aspect of maintaining the device’s performance, hygiene, and safety. Adherence to manufacturer-recommended replacement intervals ensures the device consistently delivers accurately mixed formula, free from potential contamination resulting from worn or degraded parts.

- Mixing Funnel Longevity

The mixing funnel, responsible for dispensing the correct amount of formula, is subject to wear and tear from repeated use and cleaning. Over time, microscopic cracks may develop, affecting dispensing accuracy and potentially harboring bacteria. The manufacturer typically recommends replacement every 3-6 months, or sooner if damage is observed. Failure to replace the funnel as needed may result in inconsistent formula concentrations and a heightened risk of contamination.

- Water Tank Integrity

While the water tank itself may not require frequent replacement, its components, such as the filter (if applicable) and seals, do. Mineral buildup and general degradation can compromise the filter’s ability to purify the water, and worn seals may lead to leaks or reduced water pressure. Filter replacement should align with manufacturer guidelines, usually every 1-2 months, while seals should be inspected regularly and replaced at any sign of damage.

- Powder Container Components

The powder container’s lid and sealing mechanisms are essential for maintaining the dryness and integrity of the formula powder. Over time, the seal may lose its effectiveness, allowing moisture to enter and causing the powder to clump or spoil. Regular inspection of the lid and replacement as needed typically every 6-12 months, or sooner if signs of damage or wear are evident is crucial for preventing formula degradation.

- Internal Tubing and Connections

Internal tubing and connectors are susceptible to wear and tear from constant exposure to water and formula. Regular inspection for cracks, leaks, or blockages is necessary. While the manufacturer may not provide a specific replacement schedule, any evidence of damage or degradation warrants immediate replacement to ensure accurate dispensing and prevent internal contamination.

In summary, a proactive approach to the replacement schedule for Baby Brezza Formula Pro Advanced components is essential. It maintains the device’s accuracy, prevents bacterial contamination, and ensures the safe preparation of infant formula. Deviations from the recommended schedule or neglect of component integrity can compromise the device’s intended benefits and potentially pose health risks to the infant.

5. Interchangeability

Interchangeability among Baby Brezza Formula Pro Advanced components is limited and largely discouraged, primarily due to the precise engineering required for accurate formula preparation. While some parts may appear similar across different models or production runs, subtle variations in dimensions, materials, or calibration can drastically affect the machine’s performance. Attempting to interchange parts not specifically designated as compatible can lead to inaccurate formula mixing, potentially resulting in under- or over-concentration, both of which pose health risks to the infant. The machine relies on a precise interplay between each component; for instance, a slightly different funnel design may disrupt the water-to-powder ratio, altering the nutritional content of the final product.

The lack of complete interchangeability stems from the machine’s automated operation. Each component is designed to work within a narrow tolerance range, ensuring consistent and safe formula preparation. While some third-party manufacturers may offer aftermarket parts that claim compatibility, their performance and safety are not guaranteed by Baby Brezza. Utilizing these unofficial components can void the warranty and increase the risk of malfunction. Furthermore, seemingly identical parts may have undergone design revisions or material changes without explicit notification, making direct swaps problematic. An example is the mixing funnel, where minor variations in the internal structure can influence the powder dispensing rate, even if the exterior dimensions appear the same.

In conclusion, while the concept of interchangeable components may seem appealing from a convenience or cost-saving perspective, it is not advisable for Baby Brezza Formula Pro Advanced units. The potential for compromised performance and safety outweighs any perceived benefits. Adhering to the manufacturer’s recommendations regarding replacement parts and avoiding unauthorized substitutions is crucial for ensuring the reliable and safe operation of the machine and protecting the health of the infant consuming the prepared formula. Users should always consult the device’s manual and contact customer support for clarification on compatible replacement parts.

6. Proper Storage

Proper storage of Baby Brezza Formula Pro Advanced components is integral to maintaining their integrity and ensuring the device operates safely and effectively. Inadequate storage practices can lead to material degradation, contamination, and compromised performance, undermining the appliance’s intended benefits.

- Protection from Environmental Factors

Storage locations should shield components from direct sunlight, extreme temperatures, and excessive humidity. Prolonged exposure to ultraviolet radiation can cause plastics to become brittle and crack, while temperature fluctuations can lead to warping or dimensional changes. Humid environments promote the growth of mold and bacteria, potentially contaminating parts that come into contact with formula. Storing components in a cool, dry place helps preserve their structural integrity and prevents microbial proliferation.

- Prevention of Physical Damage

Proper storage involves protecting components from physical impact or abrasion. Stacking heavy objects on top of parts can cause deformation or breakage, while rough handling can lead to scratches and cracks that compromise their functionality. Using designated storage containers or padded compartments prevents accidental damage during handling and transportation. Ensuring components are stored away from sharp objects or abrasive surfaces minimizes the risk of surface damage that can trap bacteria or affect performance.

- Maintaining Hygiene and Sanitization

Prior to storage, all components should be thoroughly cleaned and sanitized according to the manufacturer’s instructions. Residual formula or moisture can promote bacterial growth during storage, negating the benefits of prior cleaning efforts. Storing components in airtight containers or resealable bags minimizes exposure to airborne contaminants and helps maintain their sanitized state. Regular inspection of stored components is recommended to identify any signs of contamination or degradation that may necessitate re-cleaning or replacement.

- Organization and Accessibility

Implementing an organized storage system ensures components are readily accessible when needed and prevents unnecessary handling that can lead to damage or contamination. Labeling storage containers and designating specific locations for each part facilitates quick retrieval and reduces the likelihood of misplacing or damaging components. Maintaining a clear and organized storage area also promotes efficient maintenance and prevents the accidental mixing of parts from different machines or models.

In conclusion, diligent attention to the proper storage of Baby Brezza Formula Pro Advanced components is essential for maximizing the device’s lifespan, maintaining hygiene standards, and ensuring consistent and reliable formula preparation. Improper storage practices can negate the benefits of regular cleaning and maintenance, potentially compromising infant health. Therefore, prioritizing proper storage is a crucial aspect of responsible ownership and safe operation of the appliance.

7. Accurate Calibration

Accurate calibration is intrinsically linked to the proper functioning of Baby Brezza Formula Pro Advanced components. The device relies on precise measurements of both formula powder and water to deliver consistent and safe feedings. Calibration ensures that the intended quantity of each substance is accurately dispensed, maintaining the desired nutritional profile of the prepared formula. Without accurate calibration, even perfectly maintained parts cannot guarantee the correct formula-to-water ratio. This can lead to either under-concentrated formula, which may not provide adequate nutrition, or over-concentrated formula, which can burden an infant’s kidneys. For instance, if the powder dispensing mechanism is not accurately calibrated, it might dispense too little or too much formula, directly affecting the caloric density of the feeding.

The practical significance of understanding the connection between accurate calibration and the components manifests in several ways. First, users need to recognize that simply replacing a part does not automatically resolve potential issues with formula consistency; calibration may be necessary after certain component replacements. Second, awareness of the calibration process enables users to troubleshoot problems more effectively. For example, if a user observes that the prepared formula consistently appears too watery or too thick, they can suspect a calibration issue rather than solely focusing on component malfunctions. Third, routine calibration, as recommended by the manufacturer, becomes a crucial maintenance step, ensuring the device operates within acceptable performance parameters. Regularly calibrated components also experience less stress, leading to extended part lifespan.

In summary, accurate calibration is not merely a supplementary feature but a foundational requirement for the Baby Brezza Formula Pro Advanced. It complements the physical components by ensuring they function in harmony to deliver safe and nutritionally appropriate feedings. While maintaining the individual parts is crucial, regular calibration ties these efforts together, mitigating the risk of inaccurate formula preparation. Ignoring or neglecting this aspect can undermine the intended benefits of the device, posing potential health risks to the infant.

Frequently Asked Questions

This section addresses common inquiries regarding components associated with the Baby Brezza Formula Pro Advanced, focusing on functionality, maintenance, and potential issues.

Question 1: What constitutes the essential parts of the Baby Brezza Formula Pro Advanced?

The essential parts include the water tank, powder container, mixing funnel, measuring wheel, and dispensing nozzle. These components work in concert to automate formula preparation.

Question 2: How often should the mixing funnel be cleaned?

The mixing funnel requires cleaning after every four uses, or at least once daily. This prevents formula buildup and ensures accurate mixing ratios.

Question 3: Where can replacement components be obtained?

Replacement components are typically available through the manufacturer’s website, authorized retailers, and select online marketplaces. Ensure parts are genuine to maintain warranty and proper function.

Question 4: What material are the primary components constructed from?

The primary components are generally constructed from BPA-free plastic, designed for food safety and heat resistance. Specific material types may vary by component.

Question 5: Is it necessary to calibrate the machine after replacing a component?

Calibration may be necessary after replacing certain components, particularly the mixing funnel or measuring wheel. Consult the manufacturer’s instructions for specific guidance.

Question 6: What steps should be taken if a component appears damaged?

If a component exhibits any signs of damage, such as cracks or warping, discontinue use immediately and replace the part. Operating with damaged components can compromise formula preparation.

Proper understanding of these parts and adhering to the cleaning and maintenance guidelines can prolong the appliance’s lifespan.

The subsequent section will focus on troubleshooting common issues with baby brezza formula pro parts.

Baby Brezza Formula Pro Parts

This exploration has underscored the criticality of individual components within the Baby Brezza Formula Pro Advanced. From material composition to cleaning frequency and replacement schedules, each aspect contributes to the device’s overall performance and the safety of infant formula preparation. Neglecting these details can compromise the accuracy of mixing ratios and increase the risk of bacterial contamination, directly impacting infant health.

Therefore, meticulous attention to the care and maintenance of these integral components is not merely a matter of convenience, but a necessity. Consistent adherence to manufacturer guidelines, alongside proactive monitoring for signs of wear or damage, is paramount. The long-term reliability and safety of the Baby Brezza Formula Pro Advanced are directly dependent on a thorough understanding of, and responsible engagement with, its individual parts.