Receptacles specifically designed for storing and dispensing powdered infant nutrition are essential components of modern infant feeding practices. These vessels, often composed of plastic or metal, serve to maintain the sterility and freshness of the contents, ensuring the safe preparation of nourishment for newborns and infants. Examples include portable dispensers with pre-measured compartments, airtight tubs with scoops, and refillable pouches.

The significance of appropriate storage cannot be overstated. Proper containment prevents contamination, safeguards the nutritional integrity of the product, and facilitates accurate portioning. Historically, improvised methods were employed, often leading to spoilage or inaccurate dilutions. The development of specialized packaging represents a significant advancement, contributing to reduced risk of illness and improved infant health outcomes. These advancements promote convenience and ease of use for caregivers.

The subsequent sections will explore the materials used in their construction, the various designs available, guidelines for cleaning and sanitizing, and considerations for sustainable options. Furthermore, information on proper storage techniques and safety standards will be provided, along with a review of regulatory oversight and evolving trends within the industry.

Essential Guidelines for Optimal Storage and Usage

Adherence to recommended practices for these storage units is crucial for ensuring infant safety and maximizing the nutritional value of prepared feeds. The following guidelines offer essential information for appropriate handling and maintenance.

Tip 1: Prioritize Airtight Seals: Confirm that the chosen unit features an airtight seal to prevent moisture absorption, which can lead to clumping and bacterial growth. Examine seals regularly for damage and replace if necessary.

Tip 2: Select Food-Grade Materials: Ensure the vessel is manufactured from food-grade materials that are BPA-free and compliant with relevant safety regulations. Verify certifications and material specifications before use.

Tip 3: Implement Regular Cleaning and Sanitization: Wash and sanitize the item thoroughly after each use, following the manufacturer’s instructions. Use hot, soapy water or a dishwasher-safe sanitization cycle. Allow to air dry completely before refilling.

Tip 4: Store in a Cool, Dry Place: Keep the receptacle in a cool, dry environment, away from direct sunlight, heat sources, and potential contaminants. Avoid storing near strong-smelling substances.

Tip 5: Utilize Accurate Measurement: Employ the scoop provided by the product manufacturer for precise measurement. Avoid using household spoons, as they may not deliver accurate portions.

Tip 6: Monitor Expiration Dates: Adhere strictly to the expiration date printed on the original packaging. Never transfer expired powder into the container.

Tip 7: Avoid Cross-Contamination: Dedicate one receptacle solely to formula and prevent cross-contamination with other food items or substances.

Following these guidelines minimizes the risk of contamination, preserves nutritional integrity, and ensures accurate preparation. Proper handling significantly contributes to infant health and safety.

The concluding section will provide a summary of key considerations and offer resources for further information on infant feeding practices.

1. Material Safety

The selection of materials in the fabrication of receptacles intended for powdered infant nutrition necessitates rigorous scrutiny due to potential impacts on infant health. The container’s composition directly interfaces with the product intended for consumption, thereby demanding meticulous consideration of potential leachates and inherent material properties.

- Bisphenol A (BPA) and Phthalates

The presence of BPA and phthalates in plastics raises significant concerns due to their endocrine-disrupting properties. Exposure to these chemicals, even at low levels, has been linked to adverse health effects in infants, including developmental and reproductive issues. Regulations in many regions now restrict or prohibit the use of BPA in baby bottles and feeding products. Ensuring the absence of these substances is paramount.

- Food-Grade Plastics

The utilization of food-grade plastics, such as polypropylene (PP) or polyethylene (PE), is crucial. These materials are designed to be inert and resistant to chemical leaching when in contact with food substances. Certification from regulatory bodies, such as the FDA or EFSA, provides assurance that the plastic meets established safety standards for food contact applications.

- Heavy Metals

The presence of heavy metals, such as lead, cadmium, or mercury, even in trace amounts, poses a significant risk to infant health. These metals can accumulate in the body and cause neurological damage. Manufacturers must implement rigorous testing procedures to ensure that the materials used in the container’s construction are free from heavy metal contamination.

- Migration Testing

Migration testing is a critical aspect of evaluating material safety. This process involves simulating the conditions of use, such as exposure to heat and acidic or alkaline environments, to assess the potential for chemical migration from the container into the contents. Compliance with established migration limits ensures that any potential leaching remains within acceptable safety thresholds.

The integration of stringent material selection criteria, coupled with rigorous testing protocols, is essential for mitigating potential health risks associated with the use of these containers. Prioritizing certified food-grade materials and continuously monitoring for the presence of harmful substances constitutes a critical element in safeguarding infant well-being.

2. Airtight Sealing

The preservation of powdered infant nutrition relies significantly on the integrity of its containment. Airtight sealing, therefore, is not merely a desirable feature but a fundamental requirement for receptacles designed for this purpose. Its role extends beyond simple enclosure; it actively safeguards the nutritional composition and hygienic state of the product.

- Moisture Prevention

The hygroscopic nature of powdered nutrition renders it susceptible to moisture absorption. Exposure to humidity leads to clumping, altering the texture and potentially impeding accurate measurement. An airtight seal creates a barrier, preventing moisture ingress and maintaining the powder’s free-flowing consistency. In the absence of an effective seal, even brief exposure to ambient humidity can compromise the product’s quality, necessitating its disposal.

- Contamination Control

Environmental contaminants, including airborne bacteria, mold spores, and particulate matter, pose a threat to the sterility of the powder. An airtight seal effectively isolates the contents from these external agents, minimizing the risk of microbial growth and maintaining the product’s safety for infant consumption. Failure to provide an adequate seal allows contaminants to proliferate, potentially leading to illness in vulnerable infants.

- Nutrient Preservation

Certain vitamins and nutrients present in the powder are susceptible to degradation upon exposure to oxygen. An airtight seal minimizes oxygen exposure, thereby preserving the nutritional integrity of the product over time. This is particularly crucial for maintaining the levels of essential vitamins and antioxidants, ensuring that the infant receives the intended nutritional benefits. Deficient sealing accelerates nutrient degradation, diminishing the product’s value.

- Prevention of Odor Absorption

Powdered nutrition can readily absorb odors from the surrounding environment. An airtight seal prevents the transfer of undesirable smells from the container’s surroundings into the product, maintaining its palatability and acceptability to the infant. Exposure to strong odors can alter the taste and aroma, potentially leading to feeding refusal. A robust seal mitigates this risk, ensuring consistent product quality.

The synergistic effect of these facets underscores the critical importance of airtight sealing in maintaining the quality and safety of powdered nutrition. The implementation of robust sealing mechanisms represents a non-negotiable aspect of receptacle design, directly impacting infant health outcomes. Investing in reliable sealing technology ensures that the product remains safe, nutritious, and palatable throughout its intended shelf life.

3. Accurate Measuring

The correlation between precise quantification and receptacles for powdered infant nutrition is paramount. This intersection directly affects infant health and necessitates rigorous design and implementation of measurement mechanisms within these containers.

- Consistency of Nutrient Intake

Deviation from recommended powder-to-water ratios can lead to either nutrient deficiency or over-concentration, both of which can have detrimental effects on infant development. Containers designed with integrated, accurate measuring tools, such as leveled scoops or volumetric markings, minimize the risk of inconsistent nutrient intake, promoting healthy growth trajectories.

- Osmotic Balance Regulation

Inaccurate preparation of infant nutrition can disrupt the osmotic balance in an infant’s system, potentially leading to digestive distress, dehydration, or electrolyte imbalances. Precise measuring, facilitated by properly designed scoops or dispensers within the container, ensures that the prepared formula maintains an appropriate osmotic concentration, mitigating the risk of these complications.

- Minimizing Preparation Errors

Human error during preparation is a significant concern. Container designs that incorporate clear and unambiguous measurement aids reduce the likelihood of mistakes. This includes clearly marked scoops with defined volumes, as well as easy-to-read measurement indicators on the container itself, simplifying the preparation process and decreasing the potential for inaccurate formula concentrations.

- Standardization of Feeding Practices

Accurate measuring promotes standardization across different caregivers. When containers provide consistent and reliable measurement tools, all individuals preparing the formula are more likely to adhere to recommended guidelines, ensuring that the infant receives consistent nutrition regardless of who is providing the feed. This is particularly important in settings with multiple caregivers.

Therefore, the incorporation of accurate and user-friendly measuring mechanisms within these containers is not merely a matter of convenience; it is a critical component of ensuring infant health and well-being. The design and implementation of these features should be prioritized to minimize preparation errors and promote consistent, safe feeding practices.

4. Ease of cleaning

The relationship between cleanability and vessels designed for powdered infant nutrition is a critical aspect of infant health and safety. Residue accumulation within these receptacles fosters bacterial proliferation, posing a direct threat of contamination. Complex designs with areas exacerbate this risk, making thorough sanitation difficult to achieve. Conversely, simplified designs, featuring smooth surfaces and wide openings, facilitate effortless cleaning, minimizing bacterial buildup. For instance, a container with a narrow neck and multiple internal crevices inherently poses a greater hygiene challenge than a container with a wide mouth and a single, smooth inner surface. This disparity underscores the direct impact of design on the efficacy of cleaning protocols.

The material composition also influences the ease of cleaning. Certain plastics are prone to staining and odor retention, even after rigorous washing. Conversely, materials like stainless steel and certain high-grade plastics exhibit superior resistance to staining and odor absorption, simplifying the cleaning process and ensuring a more hygienic surface. Furthermore, dishwasher compatibility is a significant factor in assessing cleanability. Receptacles that can withstand the high temperatures and detergents of a dishwasher cycle offer a distinct advantage in terms of convenience and effectiveness of sanitation. Examples include modular containers that can be fully disassembled for thorough cleaning of each component.

In summary, the degree to which a container can be easily and effectively cleaned directly correlates to the reduction of bacterial contamination and the safeguarding of infant health. Design features that prioritize simplicity, material selection that resists staining and odor retention, and dishwasher compatibility are all essential elements in ensuring the hygienic integrity of receptacles used for powdered infant nutrition. The challenges lie in balancing these hygiene-focused design considerations with other factors, such as portability and cost-effectiveness, to provide accessible and safe solutions for caregivers.

5. Portability

The attribute of portability in receptacles for powdered infant nutrition constitutes a significant factor in contemporary infant feeding practices. A mobile container design facilitates convenient and hygienic preparation of nourishment while away from domestic settings. The absence of readily available prepared formula necessitates on-demand mixing, making portability an essential attribute. This consideration enables caregivers to adhere to recommended feeding schedules irrespective of location. For example, travel, childcare facilities, and public spaces often lack the infrastructure for convenient formula preparation, emphasizing the need for portable solutions.

Design parameters influencing portability include size, weight, and the inclusion of features such as integrated dispensing mechanisms or secure closures. Compact, lightweight designs minimize burden during transit, while secure closures prevent spillage and contamination. Furthermore, some containers incorporate pre-measured compartments, streamlining the preparation process by eliminating the need for separate measuring devices. An illustrative example is a container designed to hold pre-portioned amounts of powder for multiple feedings, simplifying preparation and reducing the risk of contamination during travel. These features contribute to the overall usability and practicality of the receptacle in mobile settings.

In summary, portability is an indispensable attribute of receptacles intended for powdered infant nutrition. Its presence empowers caregivers to maintain consistent feeding practices in diverse environments, promoting infant health and well-being. Challenges remain in balancing portability with other design considerations, such as volume capacity and ease of cleaning; however, the benefits of portable solutions in facilitating convenient and hygienic formula preparation are undeniable.

6. Durability

The longevity and resilience of receptacles for powdered infant nutrition, termed durability, constitute a critical factor impacting consumer safety and economic considerations. The capacity of such a container to withstand repeated use, cleaning cycles, and potential impacts directly influences its lifespan and the ongoing safety of the contained product. A lack of durability can lead to structural compromise, potentially introducing contaminants or rendering the container unusable, necessitating premature replacement. For instance, a container constructed from brittle plastic may crack under normal handling, exposing the contents to external elements or causing physical harm to the user. The selection of robust materials and the implementation of sound manufacturing practices are, therefore, paramount in ensuring the durability of these receptacles.

Furthermore, the type of usage directly influences durability requirements. Containers intended for frequent travel necessitate a higher degree of impact resistance compared to those primarily used in a static home environment. The design must incorporate features that mitigate wear and tear, such as reinforced corners and robust closure mechanisms. A real-world example includes containers made from shatter-resistant polymers, specifically designed to withstand the rigors of transport and repeated handling. These features extend the functional lifespan of the container, reducing the need for frequent replacements and minimizing waste. The economic benefit of increased durability translates to long-term cost savings for consumers, while the environmental impact is lessened through reduced consumption of resources.

In conclusion, durability is an indispensable attribute of receptacles designed for powdered infant nutrition. Its impact extends beyond mere longevity, influencing safety, economic efficiency, and environmental sustainability. Prioritizing the selection of durable materials and the implementation of robust designs ensures that these containers can reliably perform their intended function over an extended period, safeguarding the health of infants and minimizing waste. The challenge lies in balancing durability requirements with other design considerations, such as cost-effectiveness and ease of use, to provide optimal solutions for caregivers.

7. Sterilizability

The capacity to undergo effective sterilization is a critical attribute of receptacles designed for powdered infant nutrition, directly impacting infant health outcomes. Incomplete sterilization processes permit the survival and proliferation of pathogenic microorganisms, leading to potential infections and adverse health consequences for vulnerable infants.

- Material Compatibility with Sterilization Methods

The material composition of the container must withstand the rigors of commonly employed sterilization techniques, such as boiling, steam sterilization, and chemical disinfection. Materials that degrade or leach harmful substances under such conditions are unsuitable. For example, certain plastics may release bisphenol A (BPA) when exposed to high temperatures, rendering them unsafe for repeated sterilization cycles. Polypropylene (PP) and polysulfone are examples of materials generally considered compatible with standard sterilization methods.

- Design Features Facilitating Sterilization

The design of the container should minimize areas where microorganisms can accumulate and evade sterilization. Complex geometries with narrow crevices or hard-to-reach areas hinder effective cleaning and disinfection. Simplified designs with smooth surfaces and wide openings promote thorough sterilization. Modular designs that allow for complete disassembly of the container into individual components further enhance sterilizability, as each part can be accessed and treated independently. For example, containers with integrated straws or valves often present sterilization challenges due to the difficulty of reaching and cleaning these components effectively.

- Resistance to Repeated Sterilization Cycles

Containers subjected to frequent sterilization must maintain their structural integrity and functionality over numerous cycles. Repeated exposure to high temperatures, harsh chemicals, or prolonged immersion in water can degrade certain materials, leading to cracking, warping, or loss of sealing capacity. Materials with inherent resistance to these stresses are preferred. For instance, borosilicate glass offers excellent resistance to thermal shock and chemical degradation, making it a suitable material for containers requiring frequent sterilization.

- Verification of Sterilization Efficacy

The effectiveness of the chosen sterilization method must be verifiable. Indicators, such as chemical strips that change color upon reaching a specific temperature, can provide visual confirmation that sterilization parameters have been met. Regular monitoring of sterilization equipment and adherence to validated protocols are essential. In healthcare settings, biological indicators containing resistant bacterial spores are often used to confirm the complete elimination of microorganisms during sterilization processes. The absence of such verification mechanisms increases the risk of undetected contamination.

The ability to effectively sterilize a container for powdered infant nutrition is not merely a desirable feature but a fundamental requirement for safeguarding infant health. Careful consideration of material compatibility, design characteristics, resistance to repeated cycles, and verification methods is essential in selecting and utilizing these receptacles. Prioritizing sterilizability minimizes the risk of contamination and ensures the delivery of safe and nutritious feedings to infants.

Frequently Asked Questions

This section addresses common inquiries concerning vessels designed for storing and dispensing powdered infant nutrition, providing factual information to assist caregivers in making informed decisions.

Question 1: What materials are considered safest for these receptacles?

The safest materials are generally recognized as food-grade polypropylene (PP) and polyethylene (PE), free from bisphenol A (BPA), phthalates, and lead. Certification from regulatory bodies, such as the FDA, offers assurance of material safety.

Question 2: How often should these receptacles be cleaned and sterilized?

Receptacles should be thoroughly cleaned after each use with hot, soapy water. Sterilization is recommended before initial use and periodically thereafter, especially for infants with compromised immune systems. Consult manufacturer guidelines for specific sterilization instructions.

Question 3: What is the best way to ensure an airtight seal?

Examine the sealing mechanism for any signs of damage or wear. Ensure the lid or closure is properly aligned and secured. Consider using containers with gasket seals for enhanced protection against moisture and contaminants.

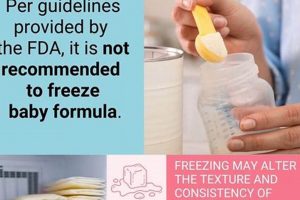

Question 4: Can these receptacles be used for storing prepared formula?

While primarily designed for powdered nutrition, some receptacles may be suitable for short-term storage of prepared formula. However, it is crucial to adhere to recommended storage times (typically no more than 24 hours in the refrigerator) to minimize bacterial growth.

Question 5: How can accurate measurement be ensured when preparing formula?

Always use the scoop provided by the manufacturer, as scoop sizes may vary. Avoid packing the powder into the scoop. Level the scoop using a flat edge to ensure consistent measurement. Refer to the formula packaging for recommended powder-to-water ratios.

Question 6: Are there any environmental considerations when choosing these receptacles?

Consider selecting receptacles made from recyclable materials or opting for reusable containers to minimize environmental impact. Explore options made from glass or stainless steel, which offer durability and recyclability benefits.

Proper selection, use, and maintenance of these receptacles are essential for ensuring infant health and safety. Adherence to recommended guidelines minimizes the risk of contamination and promotes optimal nutritional outcomes.

The following section will delve into evolving trends in the design and functionality of receptacles for infant nutrition.

Baby Formula Container

This discussion has illuminated the multifaceted considerations surrounding the baby formula container. Key aspects examined encompass material safety, the imperative for airtight sealing, the necessity of accurate measuring tools, ease of cleaning protocols, portability demands, durability requirements, and the criticality of sterilizability. Each facet contributes significantly to the safe and effective delivery of infant nutrition.

As research progresses and technological advancements emerge, continued scrutiny of design and functionality remains paramount. The ultimate objective is the development and utilization of receptacles that consistently prioritize infant health, safety, and optimal nutritional outcomes. Ongoing diligence is essential to uphold these standards and adapt to evolving knowledge in infant care.