The documentation accompanying a Baby Brezza sterilizer and dryer provides comprehensive instructions for the safe and effective operation of the appliance. This resource details the proper procedures for sterilizing and drying baby bottles, pump parts, and other feeding accessories. It typically includes diagrams, troubleshooting tips, and safety guidelines crucial for optimal usage.

Adhering to the guidelines outlined within this document ensures the hygienic preparation of infant feeding equipment, thereby reducing the risk of bacterial contamination. Proper operation, as described, extends the lifespan of the appliance and contributes to a consistently sanitary environment for infant care. Historically, reliance on boiling water for sterilization presented inconsistencies; this document provides a standardized, verifiable alternative.

The subsequent sections will delve into specifics such as preparing the appliance for initial use, loading items for sterilization, understanding the control panel functions, and executing necessary maintenance procedures as described in the official documentation.

Tips for Effective Use

The following recommendations, consistent with manufacturer guidelines, facilitate optimized performance and longevity of the sterilization and drying unit.

Tip 1: Water Quality: Utilize distilled water to minimize mineral buildup within the reservoir. Mineral deposits can impede heating efficiency and reduce the unit’s lifespan.

Tip 2: Proper Loading: Arrange bottles and accessories to ensure adequate steam circulation. Overcrowding can compromise sterilization effectiveness.

Tip 3: Cleaning Before Sterilization: Wash all items thoroughly with soap and water prior to sterilization. This removes residual milk or formula, enhancing the sterilization process.

Tip 4: Cycle Selection: Select the appropriate cycle duration based on the items being sterilized. Refer to the documentation for recommended cycle times for various materials.

Tip 5: Maintenance: Regularly clean the heating plate and reservoir with a damp cloth. Descale the unit monthly, or more frequently in hard water areas, using a descaling solution as directed in the user guide.

Tip 6: Filter Replacement: Replace the air filter according to the manufacturer’s recommended schedule. A clean filter ensures efficient drying and prevents dust contamination of sterilized items.

Tip 7: Cooling Period: Allow items to cool slightly before handling. While sterilized items are generally safe to handle immediately, excessive heat can pose a burn risk.

Adherence to these guidelines ensures thorough sterilization, efficient drying, and prolonged appliance functionality, all contributing to a safer feeding environment for the infant.

The subsequent section will provide a detailed overview of potential troubleshooting scenarios and their corresponding solutions.

1. Safety precautions

The “Safety precautions” section of the documentation is paramount for preventing injury and damage during operation of the sterilization and drying unit. Failure to adhere to these guidelines can result in burns from steam or hot surfaces, electrical hazards from improper wiring or water exposure, and damage to the appliance itself. Real-world examples include instances where users have overloaded the unit, causing it to malfunction, or have failed to allow the unit to cool before handling sterilized items, resulting in burns. The “Safety precautions” component, therefore, acts as a preventative measure, mitigating potential risks associated with high-temperature sterilization and drying processes.

Furthermore, the “Safety precautions” directly influence the longevity of the appliance. Misuse, such as using non-distilled water, can cause mineral buildup that damages internal components. Ignoring warnings against immersing the unit in water can lead to electrical shorts and permanent damage. Correct operation, as dictated by these precautions, extends the product’s life and ensures its continued safe functionality. This highlights the practical significance of thoroughly understanding and implementing these safeguards.

In summary, the “Safety precautions” within the “Baby Brezza sterilizer and dryer manual” are not mere suggestions, but essential directives. Their diligent application minimizes risks of injury, prevents damage to the appliance, and ensures its consistent, reliable performance. Disregarding them introduces the potential for negative consequences, underscoring the critical role this section plays in responsible appliance usage and infant care safety.

2. Operating instructions

The “Operating instructions” section within a Baby Brezza sterilizer and dryer document serves as the primary guide for users, detailing the precise steps necessary for the correct and safe functioning of the appliance. These instructions are critical for achieving effective sterilization and drying, ensuring the hygienic preparation of infant feeding equipment.

- Cycle Selection and Initiation

This facet outlines the different sterilization and drying cycles available, and how to select and initiate them. Instructions detail the required water levels, placement of items within the sterilizer, and the corresponding button presses to activate the chosen cycle. Failure to follow these instructions may result in incomplete sterilization or damage to the unit. For instance, selecting the wrong cycle for delicate items may cause them to melt or warp.

- Control Panel Navigation

This component elucidates the functions of each button, indicator light, and display message on the control panel. It explains how to interpret error codes, adjust settings, and monitor the progress of a cycle. Incorrectly interpreting an error code may lead to improper troubleshooting and continued malfunction. For example, an error code indicating low water levels requires immediate attention to prevent damage to the heating element.

- Loading Procedures

The “Operating instructions” specify the correct method for loading bottles, pump parts, and other accessories into the sterilizer and dryer. This includes guidelines on orientation, spacing, and maximum capacity. Improper loading can obstruct steam circulation, preventing thorough sterilization. Overloading the unit may also lead to uneven drying and potential damage to the appliance.

- Maintenance Procedures

This aspect describes the steps required for routine cleaning and descaling of the unit. It includes instructions on which cleaning agents are safe to use, how to disassemble and reassemble components, and how frequently to perform maintenance tasks. Neglecting regular maintenance can result in mineral buildup, reduced performance, and a shortened lifespan of the appliance.

The proper adherence to the “Operating instructions” detailed within the Baby Brezza sterilizer and dryer document guarantees optimal performance, prolongs the unit’s lifespan, and most importantly, ensures the safe and hygienic preparation of infant feeding equipment. These instructions mitigate risks associated with incorrect usage and contribute to a consistently sanitary feeding environment.

3. Cleaning guidelines

The “Cleaning guidelines” section within the documentation for a Baby Brezza sterilizer and dryer provides essential instructions for maintaining the unit’s hygiene and operational efficiency. This section is critical for preventing the buildup of mineral deposits and the growth of bacteria, ensuring that sterilized items are truly safe for infant use.

- Descaling Procedures

This facet delineates the steps necessary to remove mineral scale from the heating plate and reservoir. Scale buildup, a common occurrence due to mineral content in water, reduces heating efficiency and can damage the unit. The guidelines specify appropriate descaling solutions and frequencies based on water hardness. Neglecting descaling can lead to appliance malfunction and potential contamination of sterilized items. For example, failure to descale regularly in areas with hard water can result in premature failure of the heating element.

- Component Disassembly and Cleaning

This section details how to safely disassemble removable parts of the sterilizer and dryer, such as bottle racks and accessory trays, for thorough cleaning. It specifies appropriate cleaning agents and methods, avoiding harsh chemicals that could damage the components or leave harmful residues. Regular cleaning of these parts prevents the accumulation of milk residue and other contaminants, contributing to a more hygienic sterilization process. Failure to properly clean disassembled components can introduce bacteria back into the system during subsequent sterilization cycles.

- External Surface Maintenance

These guidelines instruct users on how to clean the exterior surfaces of the appliance, including the control panel and housing. It emphasizes the use of gentle cleaning agents and methods to avoid scratching or damaging the finish. Maintaining the exterior cleanliness of the unit not only improves its aesthetic appearance but also prevents the accumulation of dust and germs that could potentially contaminate the sterilized items.

- Air Filter Replacement

The “Cleaning guidelines” specify the recommended frequency for replacing the air filter, which is responsible for removing dust and particulate matter from the air used in the drying cycle. A clogged or dirty filter reduces drying efficiency and can introduce contaminants onto sterilized items. Replacing the filter according to the manufacturer’s recommendations ensures optimal drying performance and maintains the hygienic integrity of the sterilization process.

Adherence to the “Cleaning guidelines” within the Baby Brezza sterilizer and dryer manual is vital for sustaining the unit’s effectiveness and ensuring the safety of sterilized items. Proper cleaning and maintenance prevent the buildup of contaminants, prolong the appliance’s lifespan, and contribute to a sanitary environment for infant feeding.

4. Troubleshooting section

The “Troubleshooting section” within the Baby Brezza sterilizer and dryer document serves as a critical resource for resolving operational issues and ensuring the continued functionality of the appliance. It provides a systematic approach to identifying and addressing common problems, minimizing downtime and preventing potential damage.

- Error Code Interpretation

This component of the “Troubleshooting section” elucidates the meaning of specific error codes displayed by the appliance. Each error code corresponds to a particular malfunction or operational anomaly, such as low water levels, overheating, or sensor failure. The section provides potential causes for each error code and offers step-by-step instructions for resolving the issue. Misinterpreting an error code can lead to incorrect troubleshooting steps and potential exacerbation of the problem. For example, an error code indicating a heating element malfunction requires a different approach than one signaling a simple water level issue.

- Common Issue Diagnosis

Beyond error codes, the “Troubleshooting section” addresses common problems that users may encounter, such as inadequate sterilization, incomplete drying, or unusual noises during operation. It provides a diagnostic framework for identifying the underlying cause of these issues, considering factors such as loading procedures, water quality, and component cleanliness. For instance, inadequate sterilization may be attributed to overloading the unit or using hard water, while unusual noises could indicate a loose component or obstructed fan.

- Remedial Actions and Solutions

Once the cause of a problem has been identified, the “Troubleshooting section” offers specific remedial actions and solutions. These range from simple fixes, such as refilling the water reservoir or repositioning items within the unit, to more complex procedures, such as cleaning the heating plate or replacing a faulty component. The section provides clear, step-by-step instructions for implementing each solution, ensuring that users can effectively resolve the issue without requiring professional assistance. Failing to follow these instructions correctly may result in further damage to the appliance or continued malfunction.

- Preventative Measures

In addition to addressing existing problems, the “Troubleshooting section” may also include preventative measures to minimize the likelihood of future issues. These measures can include recommendations for water type, loading techniques, maintenance schedules, and safe handling practices. By implementing these preventative measures, users can proactively protect their appliance from damage and ensure its continued reliable performance. For example, regularly descaling the unit and using distilled water can prevent mineral buildup and extend the lifespan of the heating element.

In summary, the “Troubleshooting section” serves as a comprehensive guide for diagnosing and resolving operational problems with the Baby Brezza sterilizer and dryer. By providing clear explanations, step-by-step instructions, and preventative measures, this section empowers users to maintain their appliance in optimal condition and ensure the safe and hygienic preparation of infant feeding equipment.

5. Warranty information

The “Warranty information” section, integral to the Baby Brezza sterilizer and dryer document, outlines the manufacturer’s commitment to addressing defects in materials or workmanship. This section stipulates the duration of the warranty period, typically a limited timeframe from the date of purchase, and specifies the conditions under which warranty claims will be honored. A primary function of this information is to establish a legally binding agreement between the manufacturer and the consumer, protecting the consumer against unforeseen product failures within the designated period. For instance, should the heating element malfunction within the warranty period due to a manufacturing defect, the consumer, upon providing proof of purchase and adhering to the outlined procedures, is entitled to a repair or replacement of the appliance. This illustrates the direct causal link between the warranty information and the consumer’s rights in the event of product failure.

The practical significance of understanding the “Warranty information” extends beyond mere knowledge of coverage. It mandates that consumers adhere to the operational guidelines and safety precautions detailed elsewhere in the document. Misuse of the appliance, such as using non-distilled water or neglecting regular descaling as stipulated in the cleaning guidelines, may void the warranty. Consequently, the warranty information acts as an incentive for consumers to thoroughly familiarize themselves with and abide by the manufacturer’s recommendations. The consumer bears the responsibility of demonstrating that any product defect arose from normal use and not from negligence or improper handling. This underscores the interconnectedness of all sections within the document; adherence to the operating instructions is paramount for maintaining warranty eligibility. Additionally, the warranty information often includes specific procedures for submitting a claim, including contacting customer support and providing necessary documentation. Failure to follow these procedures can invalidate a legitimate claim, resulting in the consumer bearing the cost of repair or replacement.

In summary, the “Warranty information” within the Baby Brezza sterilizer and dryer manual is not merely a statement of coverage but a cornerstone of the consumer-manufacturer relationship. It establishes rights and responsibilities, promotes adherence to operational guidelines, and ensures that consumers are equipped to seek redress in the event of product defects. Understanding this section is therefore crucial for maximizing the benefits of the appliance and protecting one’s investment.

6. Parts Identification

The “Parts Identification” section within a Baby Brezza sterilizer and dryer manual is a fundamental component for effective operation and maintenance. This section provides a visual and descriptive inventory of all constituent parts, enabling users to correctly assemble, disassemble, and troubleshoot the appliance.

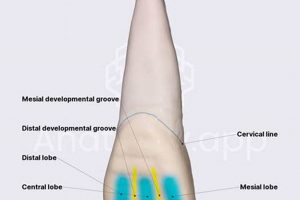

- Component Nomenclature and Diagrammatic Representation

This aspect of “Parts Identification” furnishes standardized names for each component, paired with detailed diagrams illustrating their location and orientation within the appliance. Without this clarity, users may struggle to identify parts during cleaning, repair, or replacement. For example, mistaking the “Heating Plate” for the “Reservoir Base” could lead to improper cleaning procedures, potentially damaging the unit. Clear nomenclature and diagrams mitigate such errors, ensuring users can accurately identify and handle each component.

- Interconnectivity and Assembly Instructions

The “Parts Identification” often extends to detailing how individual parts connect and assemble. This is crucial when disassembling the unit for thorough cleaning, a process recommended in the manual. Incorrect reassembly, resulting from inadequate “Parts Identification,” can compromise the appliance’s functionality. For instance, failing to properly reattach the “Steam Deflector” could lead to uneven sterilization. The instruction on interconnectivity and assembly enables the user to correctly reassemble the parts.

- Material Composition and Compatibility

This element of “Parts Identification,” sometimes implied rather than explicitly stated, informs users about the materials used in each part. This knowledge is essential for selecting appropriate cleaning agents and understanding potential limitations. For example, identifying that the “Bottle Rack” is made of heat-resistant plastic prevents the use of abrasive cleaners that could damage the surface. Understanding material composition safeguards the components.

- Replacement Part Information

The “Parts Identification” directly facilitates the acquisition of replacement parts. By clearly naming and depicting each component, the manual enables users to accurately order replacements when necessary. This is particularly relevant for parts prone to wear and tear, such as the “Air Filter” or “Gasket Seal.” Precise “Parts Identification” ensures that users obtain the correct replacements, avoiding compatibility issues and prolonging the appliance’s lifespan.

In conclusion, the “Parts Identification” section of a Baby Brezza sterilizer and dryer manual is indispensable for proper usage, maintenance, and repair. By providing clear visual and descriptive information, it empowers users to effectively manage their appliance, ensuring both its longevity and the safe sterilization of infant feeding equipment. Without accurate part identification, the user risks incorrect operations, assembly, and potential repairs.

7. Descaling process

The “descaling process,” as detailed within a Baby Brezza sterilizer and dryer manual, is a critical maintenance procedure directly impacting the appliance’s functionality and longevity. The accumulation of mineral deposits, primarily calcium and magnesium carbonates from water, impedes heating efficiency and can lead to component failure. The manual provides specific instructions regarding the frequency, methodology, and appropriate descaling agents to counteract this buildup. Failure to adhere to these instructions results in reduced steam generation, extended sterilization cycles, and potential damage to the heating element. Real-world examples include instances where neglected descaling has rendered the appliance unusable due to severe mineral encrustation, necessitating costly repairs or premature replacement. The descaling process is thus not merely a suggestion but a mandated step for preserving the sterilizer’s performance.

The specific descaling agent recommended within the manual is typically a mild citric acid solution or a proprietary descaling formulation. The instructions outline precise proportions and immersion times to effectively dissolve mineral deposits without damaging the appliance’s internal components. This level of detail is crucial, as using harsh chemicals or abrasive cleaning methods can corrode or degrade the plastic and metal parts, voiding the warranty and further compromising the unit’s functionality. The manual further stipulates the importance of rinsing the appliance thoroughly after descaling to remove any residual descaling agent, preventing contamination of items subsequently sterilized. A properly executed descaling process ensures consistent steam production, maintains optimal sterilization temperatures, and extends the appliance’s operational lifespan.

In conclusion, the “descaling process,” as presented in the Baby Brezza sterilizer and dryer manual, is an indispensable maintenance procedure. Its diligent execution mitigates the adverse effects of mineral buildup, preserving the appliance’s efficiency and preventing costly repairs. This process, therefore, represents a direct link between adherence to the manual’s instructions and the sustained performance and longevity of the sterilization and drying unit. Neglecting this process poses a tangible threat to the appliance’s operational integrity, underscoring the importance of the manual as a guide for responsible appliance management.

Frequently Asked Questions

The following section addresses common inquiries regarding the Baby Brezza sterilizer and dryer, drawing directly from the appliance’s manual to provide accurate and reliable information.

Question 1: What type of water should be used in the sterilizer?

Distilled water is recommended to minimize mineral buildup within the reservoir. Tap water contains minerals that can deposit on the heating plate, reducing efficiency and potentially damaging the unit over time.

Question 2: How often should the sterilizer be descaled?

The descaling frequency depends on the hardness of the water being used. In areas with hard water, monthly descaling is advisable. In areas with softer water, descaling every two to three months may suffice. Consult the manual for detailed instructions on the descaling process.

Question 3: Can bottles and accessories be overloaded in the sterilizer?

Overloading the unit is not recommended. Proper steam circulation is essential for effective sterilization. Overcrowding can obstruct steam flow, leading to incomplete sterilization and potentially damaging the appliance.

Question 4: What should be done if an error code appears on the control panel?

Refer to the “Troubleshooting” section of the manual. Error codes indicate specific malfunctions or operational issues. The manual provides explanations for each code and offers step-by-step instructions for resolving the problem.

Question 5: How often should the air filter be replaced?

The air filter should be replaced according to the manufacturer’s recommendations, typically every three to six months. A clean filter ensures efficient drying and prevents dust contamination of sterilized items.

Question 6: Is it necessary to wash items before sterilizing them?

Yes, all items should be thoroughly washed with soap and water prior to sterilization. Washing removes residual milk or formula, which can impede the sterilization process and potentially compromise the hygiene of the items.

These frequently asked questions offer a condensed overview of key operational aspects. For comprehensive guidance, consult the complete Baby Brezza sterilizer and dryer manual.

The subsequent section will address common misconceptions surrounding the use of sterilization and drying appliances.

Conclusion

The preceding sections have comprehensively explored the various facets of the “baby brezza sterilizer and dryer manual,” from its role in ensuring safe operation to its importance in maintaining the appliance’s longevity and effectiveness. The examination has highlighted the manual’s critical instructions regarding safety precautions, operational procedures, cleaning guidelines, troubleshooting techniques, warranty information, parts identification, and the descaling process. Each element contributes to a holistic understanding of the appliance and its responsible utilization.

Consistent adherence to the guidelines outlined within the “baby brezza sterilizer and dryer manual” remains paramount for maximizing the appliance’s benefits and minimizing potential risks. The information it contains directly impacts the hygiene of infant feeding equipment and, ultimately, the well-being of the child. Diligent application of these principles constitutes a commitment to responsible and informed infant care practices.