The central question concerns whether a specific appliance, the Baby Brezza, renders infant formula free from microorganisms. Sterilization, in this context, refers to the process of eliminating bacteria, viruses, fungi, and spores that could potentially cause illness in infants. Some devices use heat, steam, or chemical solutions to achieve this level of microbial reduction. For example, traditional bottle sterilizers employ steam to kill pathogens that may be present on baby bottles.

Ensuring the safety of infant feeding is paramount. Historically, boiling water was a common method for sanitizing feeding equipment. Modern sterilization methods aim to replicate this level of safety with increased convenience and speed. This is particularly vital for premature or immunocompromised infants, as they are more susceptible to infections from contaminated formula or feeding equipment.

The following discussion will examine the capabilities of the Baby Brezza formula maker, specifically addressing its design and function in relation to microbial reduction. It will focus on clarifying whether the device’s operation cycle includes a dedicated sterilization phase comparable to dedicated sterilization units or traditional boiling methods, and the implications for infant health.

Considerations Regarding Formula Preparation and the Baby Brezza

The following tips address key aspects of formula preparation, particularly in relation to the Baby Brezza, focusing on safety and best practices.

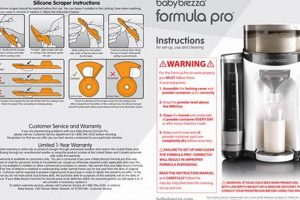

Tip 1: Consult the manufacturer’s instructions for the Baby Brezza meticulously. Understanding the specific model’s capabilities and limitations is crucial for safe operation. The user manual should detail any sanitization procedures the device performs or requires.

Tip 2: Acknowledge that the Baby Brezza automates formula mixing and warming but may not include a dedicated sterilization function for the formula itself or internal components. Verify if the device has a self-cleaning cycle and its efficacy against pathogens.

Tip 3: Independently sterilize bottles and nipples using a dedicated steam sterilizer, boiling water, or dishwasher with a sanitization cycle. Regular sterilization of feeding equipment helps minimize the risk of bacterial contamination, regardless of the formula preparation method.

Tip 4: Use only distilled or sterilized water in the Baby Brezza, if the device does not have its own water sterilization system. Tap water may contain bacteria or minerals that can compromise infant health or the device’s performance.

Tip 5: Prepare only the amount of formula needed for a single feeding. Discard any leftover formula after an hour. Bacteria can multiply rapidly in prepared formula at room temperature, increasing the risk of illness.

Tip 6: Regularly clean the Baby Brezza according to the manufacturer’s recommendations. Disassemble and wash all parts that come into contact with formula to prevent the buildup of residue and bacterial growth.

Tip 7: Monitor the Baby Brezza for any signs of malfunction or contamination, such as unusual odors, discoloration, or inconsistent mixing. Address any issues promptly to ensure the device is operating safely and effectively.

Adhering to these guidelines minimizes the risk of bacterial contamination during formula preparation. Safe practices related to both equipment hygiene and formula handling are vital for infant health.

The next section will conclude the analysis of the Baby Brezza and its role in formula preparation, offering a final perspective on best practices.

1. Microbial Reduction Process

The microbial reduction process is a critical component when evaluating the capability of any device designed for infant feeding preparation. Its efficacy directly determines whether potentially harmful microorganisms are eliminated or sufficiently reduced to safe levels for consumption. In the context of the Baby Brezza, assessing whether it employs a process that achieves significant microbial reduction is central to understanding if the appliance can be accurately described as sterilizing formula.

The absence of a validated microbial reduction process implies a reliance on external factors, such as pre-sterilized water and properly sanitized bottles, to maintain hygienic standards. The Baby Brezza primarily automates the mixing and warming functions, but without a dedicated mechanism to actively diminish the microbial load within the formula or water, the risk of introducing contaminants remains. For example, if unsterilized water is used, or if the formula itself contains bacteria, the Baby Brezza’s mixing process will not render the resulting mixture sterile. Consequently, the understanding of microbial reduction processes and the Baby Brezza’s lack thereof is of practical significance for parents and caregivers seeking to minimize risks associated with infant feeding.

In summary, the presence or absence of a robust microbial reduction process fundamentally dictates whether a device purporting to sterilize formula is effectively achieving its stated objective. As the Baby Brezza does not incorporate such a process, it is incumbent upon the user to ensure all components and materials are properly sterilized before use. Understanding this limitation allows for more informed decision-making regarding infant feeding safety.

2. Heating Element Capability

The heating element within a device designed for formula preparation bears a direct relationship to its potential sterilization capabilities. The ability of the heating element to reach and maintain specific temperatures is critical in determining whether the device can effectively eliminate harmful microorganisms from the water used in formula preparation.

- Temperature Thresholds for Sterilization

True sterilization requires achieving temperatures that denature proteins and destroy microbial life. Typically, this involves temperatures at or above 100C (212F). A heating element capable of reaching and sustaining such temperatures for a specified duration is essential for effectively sterilizing water. If the element only warms water to feeding temperature (approximately 40C or 104F), it will not eliminate potentially harmful bacteria.

- Heating Element Design and Control

The design and control mechanisms of the heating element dictate the consistency and accuracy of temperature delivery. A poorly designed element may exhibit temperature fluctuations or uneven heating, compromising its ability to effectively sterilize. Similarly, inaccurate temperature controls can lead to insufficient heating, rendering the sterilization process ineffective. Therefore, precise engineering and quality control are paramount.

- Water Volume and Heating Time

The volume of water being heated and the time it is exposed to sterilizing temperatures are crucial factors. A larger volume of water will require a more powerful heating element and a longer heating time to achieve complete sterilization. Insufficient heating time, even at the appropriate temperature, can result in incomplete microbial elimination. Proper calibration of heating time relative to water volume is thus essential for effective sterilization.

- Material Compatibility and Safety

The material composition of the heating element and its compatibility with water are vital for safety and performance. Materials that leach contaminants into the water during heating can pose health risks. Furthermore, the heating element must be designed to prevent overheating and potential hazards, such as electrical shorts or scalding. Safety certifications and adherence to relevant standards are important considerations.

In summary, the “Heating Element Capability” is a core factor in evaluating whether a Baby Brezza or similar device can truly sterilize formula. Achieving and maintaining proper sterilization temperatures, precise temperature control, appropriate heating times, and material safety are all critical elements. If the heating element is not designed to meet these criteria, the device cannot be considered capable of effectively sterilizing formula.

3. Cleaning Cycle Efficacy

Cleaning cycle efficacy is directly related to the question of whether the Baby Brezza sterilizes formula. A cleaning cycle, even if present, does not inherently equate to sterilization. The effectiveness of the cleaning cycle in eliminating bacteria, viruses, and other microorganisms is the determining factor. If the cleaning cycle is designed solely to remove formula residue and prevent clogging, without achieving a level of microbial reduction comparable to boiling or steam sterilization, it cannot be considered a sterilization process. For example, a rinse cycle that uses only room-temperature water and does not incorporate a sanitizing agent will likely remove visible residue but will not eliminate harmful bacteria such as Cronobacter sakazakii, which can cause serious infections in infants.

The type of cleaning agents used and the temperatures reached during the cleaning cycle are critical. Cleaning cycles that employ hot water at temperatures sufficient to kill pathogens, or that incorporate a sanitizing solution, are more likely to contribute to microbial reduction. However, even with these measures, it is important to verify whether the cleaning cycle has been independently tested and certified to achieve a specific level of sterilization. Manufacturers sometimes claim a cleaning cycle “sanitizes” components, but this term is less stringent than “sterilizes” and may not guarantee the complete elimination of all harmful microorganisms. It is necessary to examine the specific parameters of the cleaning cycle to assess its true efficacy.

In conclusion, the presence of a cleaning cycle in the Baby Brezza does not automatically imply the sterilization of formula or internal components. The cycle’s design, including the temperature achieved, the duration of the cycle, and the use of sanitizing agents, determines its actual ability to reduce microbial contamination. Users should independently sterilize bottles and follow recommended hygiene practices for formula preparation, irrespective of any cleaning cycle function. The importance of understanding the limitations of the cleaning cycle in terms of sterilization cannot be overstated when considering infant health and safety.

4. Water Source Safety

The safety of the water source directly impacts the validity of any claim that a device, such as the Baby Brezza, sterilizes formula. Even if a formula preparation machine incorporates features intended to reduce microbial contamination, the initial presence of pathogens in the water supply can negate those efforts. If the water used is not sterile prior to entering the device, any subsequent heating or filtering processes may prove inadequate to eliminate all harmful microorganisms. Cronobacter sakazakii, for example, can be present in tap water and pose a significant risk to infants. Therefore, the question of whether a device sterilizes formula is fundamentally intertwined with the quality and safety of the water source.

Consider the scenario where a Baby Brezza heats tap water. If that tap water contains bacteria, the warming process alone will not necessarily kill those bacteria. Some bacteria thrive at warmer temperatures. Consequently, the formula prepared with this water would not be sterile, regardless of any automated mixing or dispensing features. Alternatively, if distilled or previously boiled and cooled water is used, the risk of contamination is significantly reduced. The initial microbial load entering the system is lower, increasing the effectiveness of any sanitization or heating processes within the device. The selection of an appropriate water source, therefore, is a critical control measure, independent of the machine’s capabilities.

In conclusion, the assurance of water source safety is paramount to the overall hygiene of formula preparation. Even with advanced formula-making machines, the use of non-sterile water undermines any sterilization efforts. Users must prioritize the use of distilled, sterilized, or previously boiled water to ensure that the formula prepared is safe for infant consumption. Understanding this direct relationship between water source safety and the potential for formula sterilization is essential for protecting infant health.

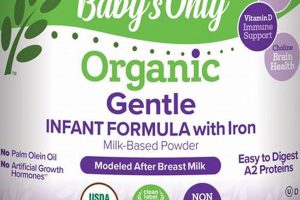

5. Formula Powder Handling

The manner in which formula powder is handled is intrinsically linked to the question of whether a device such as the Baby Brezza sterilizes formula. Formula powder, even when produced under stringent conditions, is not inherently sterile. It can harbor bacteria, notably Cronobacter sakazakii, which presents a significant risk to infants, especially those who are premature or immunocompromised. If formula powder is contaminated, and the preparation device does not actively sterilize it, the resulting mixture will also be contaminated. Therefore, the effectiveness of a device in producing sterile formula is directly contingent upon the hygienic handling of the powder itself. For instance, if a user employs a non-sterile scoop or stores the powder in an unsealed container, the introduction of pathogens compromises the integrity of the entire preparation process. The Baby Brezza, which automates the mixing of powder and water, does not eliminate any pre-existing contaminants within the powder. Thus, regardless of the device’s functionality, the formula will not be sterile if the powder is not handled with appropriate care.

Practical implications extend beyond mere storage and scooping. The cleaning and sanitization of measuring devices, storage containers, and even the external packaging of the formula are essential considerations. A real-world example illustrates this: if a scoop is washed with contaminated water and then used to measure formula, the bacteria transferred from the water to the scoop will subsequently contaminate the powder. Similarly, if the formula container is stored in a damp or unclean environment, it can become a breeding ground for microorganisms that can then migrate into the powder. Therefore, implementing rigorous hygiene protocols during every stage of formula powder handling becomes a de facto requirement for minimizing risks, irrespective of any automated preparation system. This includes the use of clean, dry hands, designated and sanitized measuring implements, and proper resealing of formula containers to prevent exposure to environmental contaminants.

In conclusion, while a device like the Baby Brezza automates formula preparation, it does not negate the imperative of meticulous formula powder handling. Since formula powder is not sterile and the device lacks sterilization capabilities, the onus rests upon the user to minimize contamination risks at every step. Proper storage, sanitized measuring tools, and diligent hygiene practices are indispensable for ensuring the safety of infant formula, irrespective of the automation employed by the preparation system. The understanding that powder handling remains a crucial control point, despite technological advancements, is paramount for protecting infant health.

6. Bottle Sanitization Needs

The necessity for bottle sanitization is a critical consideration when evaluating whether a device, such as the Baby Brezza, effectively sterilizes formula. While the device may automate formula mixing and warming, it does not inherently address the potential for contamination originating from the feeding bottles themselves. Proper bottle sanitization protocols remain essential to mitigate risks to infant health.

- Elimination of Biofilms and Bacteria

Biofilms, complex communities of microorganisms, can form on the surfaces of feeding bottles and nipples, providing a haven for bacteria such as E. coli and Salmonella. These bacteria can cause gastrointestinal illness in infants. Effective sanitization methods, such as boiling or steam sterilization, are necessary to eliminate these biofilms and reduce the bacterial load to safe levels. The Baby Brezza’s formula preparation process does not address these pre-existing contaminants within the bottles.

- Residual Contamination from Washing

Washing bottles with soap and water, while necessary, does not guarantee complete removal of all microorganisms. Residual formula and milk residue can provide a breeding ground for bacteria, even after thorough washing. Tap water itself may contain bacteria that can colonize the bottle’s surface. Consequently, sanitization is a crucial step to eliminate any remaining contaminants after washing, before the bottle is filled with prepared formula. The absence of bottle sanitization negates any potential reduction of microbial risk achieved by the Baby Brezza itself.

- Importance for Immunocompromised Infants

Immunocompromised or premature infants are particularly vulnerable to infections from contaminated feeding equipment. Their immune systems are less capable of fighting off pathogens, making strict adherence to sanitization protocols paramount. For these infants, the reliance solely on the Baby Brezza’s mixing and warming functions is insufficient, and dedicated bottle sanitization is an absolute requirement to minimize the risk of serious illness.

- Proper Sanitization Methods

Effective sanitization methods include boiling bottles and nipples for five minutes, using a steam sterilizer according to the manufacturer’s instructions, or utilizing a dishwasher with a sanitization cycle. Chemical sanitization with bleach solutions is also an option, but requires careful rinsing to remove any residual chemicals. Regardless of the chosen method, consistent and thorough sanitization of bottles and nipples is vital to minimize the risk of bacterial contamination, irrespective of the use of automated formula preparation devices.

In summary, bottle sanitization needs remain a critical aspect of safe infant feeding practices, even when utilizing a device such as the Baby Brezza. The device’s capabilities do not negate the necessity for proper bottle sanitization to minimize the risk of bacterial contamination. Consistent application of appropriate sanitization methods is essential for protecting infant health, especially for vulnerable populations.

7. User Responsibility Factors

The extent to which a Baby Brezza sterilizes formula is directly mediated by user responsibility factors. The device itself provides a degree of automation in mixing and warming, but it does not absolve the user of the responsibility for maintaining hygienic conditions and adhering to safe preparation practices. In cases where users neglect proper sanitation procedures or fail to follow manufacturer guidelines, the potential benefits of the machine are undermined, and the risk of contamination is significantly elevated. For example, if a user adds tap water containing bacteria to the Baby Brezza, the machine’s operation will not sterilize that water; consequently, the resulting formula will also be contaminated.

Consider the ramifications of irregular cleaning and maintenance. If a user fails to routinely clean the internal components of the Baby Brezza, formula residue can accumulate, providing a breeding ground for bacteria. This bacterial buildup can then contaminate subsequent batches of formula, regardless of whether the machine itself is functioning correctly. Similarly, the user’s choice of water and formula powder significantly influences the safety of the final product. Using non-sterile water or improperly stored formula powder introduces contaminants that the Baby Brezza is not designed to eliminate. User adherence to best practices, such as using distilled water, sanitizing bottles, and properly storing formula, is therefore crucial for ensuring the safety of infant feeding.

In conclusion, user responsibility factors represent a critical control point in the overall process of formula preparation. The Baby Brezza, while offering convenience, does not provide a foolproof solution for ensuring sterile formula. Users must actively engage in practices that minimize contamination risks, including meticulous cleaning, proper water selection, and careful handling of formula powder. The effective use of the Baby Brezza, and by extension, the production of safe formula, is ultimately dependent upon the responsible actions of the user, with the understanding that the machine does not compensate for lapses in hygiene and adherence to safety guidelines.

Frequently Asked Questions

The following section addresses common inquiries regarding the Baby Brezza and its role in sterilizing infant formula, providing factual information to clarify its capabilities and limitations.

Question 1: Does the Baby Brezza eliminate bacteria from formula powder?

The Baby Brezza does not sterilize formula powder. Formula powder is not inherently sterile and may contain bacteria. The device mixes formula and water but does not have a sterilization function for the powder itself.

Question 2: Does the Baby Brezza sterilize the water used to prepare formula?

The Baby Brezza warms water to a specified temperature, but it does not necessarily sterilize the water. The water must be sterile before it is added to the device to ensure formula safety. Distilled or previously boiled water is recommended.

Question 3: Does the Baby Brezza’s cleaning cycle sterilize its internal components?

The cleaning cycle is designed to remove formula residue, but it is not a sterilization process. The internal components of the Baby Brezza should be periodically cleaned and sanitized separately, following the manufacturer’s instructions.

Question 4: Can the Baby Brezza replace a dedicated bottle sterilizer?

The Baby Brezza does not replace the need for a dedicated bottle sterilizer. Bottles and nipples must be sterilized separately using steam sterilization, boiling water, or another approved method to eliminate harmful bacteria.

Question 5: What steps should be taken to ensure formula prepared with the Baby Brezza is safe?

To ensure safety, use sterile water, sterilize bottles and nipples separately, follow proper formula powder handling practices, and regularly clean and sanitize the Baby Brezza according to the manufacturer’s guidelines.

Question 6: Where can I find information on the specific cleaning and sanitization procedures for the Baby Brezza model I own?

Consult the user manual for the specific Baby Brezza model in question. It contains detailed instructions on recommended cleaning and sanitization procedures to ensure the device operates safely and effectively.

In summary, while the Baby Brezza provides convenience in formula preparation, it does not sterilize formula. Users must adhere to established sanitation guidelines and best practices to minimize contamination risks.

The following section will provide concluding remarks summarizing the main points related to the Baby Brezza and formula sterilization.

Conclusion

This article comprehensively addressed the central inquiry: does Baby Brezza sterilize formula? The analysis revealed that while the Baby Brezza automates formula mixing and warming, it does not incorporate a dedicated sterilization process. Critical components such as microbial reduction, heating element capability, cleaning cycle efficacy, water source safety, formula powder handling, and bottle sanitization needs were examined. The investigation consistently demonstrates that the Baby Brezza, in its operational design, lacks the capacity to eliminate harmful microorganisms present in either the formula powder or water. Therefore, it cannot be accurately described as a sterilizing device.

In light of these findings, adherence to established sterilization protocols remains paramount. Users must independently sterilize bottles and water, as well as practice stringent hygiene measures when handling formula powder, irrespective of the Baby Brezza’s functionality. The ultimate responsibility for ensuring infant feeding safety rests with the caregiver, who must recognize the limitations of automated preparation systems and proactively implement appropriate sterilization procedures. The health and well-being of infants depend upon a clear understanding of these principles and consistent application of best practices.