Small feeding containers, designed to hold approximately 60 milliliters of liquid, are frequently utilized for newborns and infants in their early stages of development. These receptacles provide a controlled method for delivering nourishment, typically formula or expressed breast milk, to infants with limited appetites or specific dietary needs.

The use of these smaller-volume containers can be beneficial in preventing overfeeding, minimizing instances of spit-up, and allowing for more frequent, smaller meals, which can be particularly advantageous for premature infants or those with reflux. Historically, standardized feeding implements have played a crucial role in ensuring consistent nutritional intake and simplifying infant care practices for parents and caregivers.

The subsequent sections will delve into a more detailed analysis of materials used in their construction, cleaning and sterilization protocols, appropriate use guidelines, and considerations for selecting the optimal option based on individual infant needs and parental preferences.

Guidance on Utilizing Small-Volume Infant Feeding Containers

The following recommendations are designed to provide practical guidance for the effective and safe use of small feeding bottles specifically designed for infants. Proper implementation of these suggestions can contribute to improved feeding outcomes and enhanced infant well-being.

Tip 1: Portion Control is Paramount: Accurately measure the required volume of formula or breast milk to avoid overfeeding and potential digestive discomfort. A consistent volume facilitates predictable feeding schedules.

Tip 2: Prioritize Hygiene Through Sterilization: Rigorously sterilize all components, including the bottle and nipple, before initial use and regularly thereafter, especially during the first few months of an infant’s life, to minimize the risk of bacterial contamination.

Tip 3: Monitor Nipple Flow Rate: Observe the infant’s feeding behavior to ensure the nipple flow rate is appropriate. A too-rapid flow can lead to choking or gas, while a too-slow flow may cause frustration and insufficient intake.

Tip 4: Employ Proper Feeding Posture: Hold the infant in a semi-upright position during feeding to facilitate swallowing and reduce the likelihood of ear infections. Avoid feeding while the infant is lying flat.

Tip 5: Discard Remaining Contents After Feeding: Do not save leftover formula or breast milk after a feeding session. Bacteria can proliferate in the remaining contents, posing a potential health risk.

Tip 6: Gradual Transition as Infant Grows: As the infant’s appetite increases, consider transitioning to larger-volume bottles to accommodate their growing nutritional needs. Monitor intake to determine the appropriate timing.

Tip 7: Inspect for Damage Regularly: Routinely examine the bottles and nipples for any signs of wear and tear, such as cracks or discoloration. Replace damaged components immediately to prevent potential hazards.

Adherence to these guidelines promotes safe and effective infant feeding practices. These principles support optimal nutritional intake and minimize potential health risks associated with improper bottle usage.

The subsequent sections will elaborate on selecting suitable bottle materials and discuss strategies for addressing common feeding challenges.

1. Portion Control

The capacity of small infant feeding containers, approximately 60 milliliters, directly enables precise portion control during early infant feeding. This controlled volume delivery assists caregivers in adhering to recommended feeding guidelines, especially crucial for newborns with small stomach capacities. Inadequate portion management can lead to regurgitation, discomfort, or, conversely, insufficient caloric intake. The pre-measured volume inherent in these containers simplifies the process of dispensing appropriate quantities of formula or breast milk, thereby minimizing the risk of overfeeding or underfeeding scenarios.

Consider the case of a premature infant requiring frequent, small feedings. The use of these containers allows for accurate administration of prescribed nutritional dosages, ensuring the infant receives the necessary nutrients without overwhelming their digestive system. Similarly, infants prone to reflux can benefit from smaller, more frequent meals, easily facilitated with these bottles, which helps to manage symptoms and improve tolerance. The limited volume also reduces waste, as caregivers are less likely to discard large amounts of unfinished formula or breast milk, contributing to cost-effectiveness and resource conservation.

In summary, the intrinsic design of small-volume feeding implements promotes effective portion control, a critical element in supporting healthy infant growth and development. While challenges such as variations in individual infant appetite and the need for careful monitoring persist, the inherent portioning capability of these containers offers a practical and reliable tool for caregivers seeking to optimize infant feeding practices. This capability is directly linked to improved outcomes related to digestion, nutrient absorption, and overall infant well-being, and underscores the significance of portion control as a defining component of its utility.

2. Material Safety

The selection of materials used in the construction of small infant feeding containers directly impacts infant health and safety. These receptacles, designed for direct contact with infant formula or breast milk, must be manufactured from substances free from harmful chemicals and toxins to mitigate potential adverse health effects. The causal relationship is clear: unsafe materials can leach into the feeding solution, leading to ingestion of potentially dangerous substances by the infant. Therefore, material safety is not merely a desirable feature but a fundamental requirement for such products.

Examples of safe materials include BPA-free plastics, glass, and stainless steel. Bisphenol A (BPA), a chemical previously found in many plastics, has been linked to endocrine disruption and other health concerns. The widespread adoption of BPA-free plastics represents a direct response to these concerns, demonstrating the practical application of material safety principles. Glass, an inert material, provides an alternative, though its fragility requires careful handling. Stainless steel offers durability and resistance to leaching but may be less common due to manufacturing complexities and cost. The understanding of these material properties enables informed decision-making when selecting appropriate infant feeding equipment.

In summary, material safety constitutes a critical design element of small infant feeding bottles. The avoidance of harmful chemicals, combined with the selection of appropriate construction materials, directly contributes to infant well-being and mitigates potential health risks. Challenges remain in ensuring consistent adherence to safety standards across all manufacturers and products, necessitating ongoing vigilance and regulatory oversight to safeguard infant health effectively.

3. Nipple Flow

Nipple flow rate is a critical determinant of effective and safe feeding practices, especially when utilizing small-volume infant feeding containers. The rate at which liquid is dispensed from the nipple directly influences the infant’s ability to swallow, breathe, and maintain a comfortable feeding rhythm. Incompatibility between nipple flow and infant capabilities can lead to various adverse outcomes.

- Aspiration Risk

Excessively rapid nipple flow poses a significant aspiration risk, particularly in newborns. The infant may be unable to coordinate sucking, swallowing, and breathing effectively, resulting in liquid entering the airway. This risk is heightened with smaller bottles as the quick consumption can overwhelm the infant.

- Gastrointestinal Distress

Inappropriate nipple flow can contribute to gastrointestinal distress. A flow rate that is too fast can cause the infant to gulp air during feeding, leading to gas, bloating, and discomfort. Conversely, a flow that is too slow can cause frustration and prolonged feeding times, potentially resulting in fatigue and inadequate caloric intake. The small volume in 2 oz bottles underscores the need for appropriate flow to manage intake.

- Feeding Efficiency

Optimal feeding efficiency relies on a well-matched nipple flow rate. When the flow is appropriate, the infant can feed comfortably and efficiently, minimizing energy expenditure and maximizing nutrient absorption. This is particularly important for premature infants or those with compromised sucking abilities, where energy conservation is paramount. The small volume delivered in 2 oz bottles should be consumed efficiently.

- Developmental Impact

Prolonged use of an inappropriate nipple flow rate can have developmental implications. If the flow is consistently too fast, the infant may develop abnormal sucking patterns to compensate, potentially affecting oral motor development. Conversely, a consistently slow flow might discourage feeding and hinder the development of healthy feeding behaviors. Smaller bottles often need to be updated as infants grow to maintain proper feeding habits.

In summary, the relationship between nipple flow and small infant feeding containers is paramount to ensuring positive feeding outcomes. Selection of the appropriate nipple flow rate requires careful observation of the infant’s feeding behavior and adjustment as needed. Matching flow to infant capabilities promotes safe, efficient, and developmentally appropriate feeding practices, contributing to optimal infant health and well-being. The small volume delivered in these bottles makes nipple flow particularly important.

4. Sterilization methods

Effective sterilization methodologies are fundamentally intertwined with the safe and hygienic utilization of small infant feeding containers. These receptacles, frequently employed for administering nourishment to infants, demand rigorous sterilization protocols to mitigate the risk of bacterial contamination. A direct correlation exists between inadequate sterilization and the potential for introducing harmful pathogens into the infant’s digestive system, leading to infections and adverse health outcomes.

Several accepted sterilization methods exist, including boiling, steaming, and chemical disinfection. Boiling involves immersing the bottles and associated components in boiling water for a specified duration, effectively eliminating most microorganisms. Steam sterilization, often achieved through electric steam sterilizers or microwaveable bags, utilizes high-temperature steam to achieve disinfection. Chemical sterilization employs specialized solutions to eradicate pathogens; however, thorough rinsing is imperative to prevent residual chemicals from entering the infant’s system. The choice of method often depends on parental preference, availability of equipment, and adherence to manufacturer guidelines.

In summary, the practice of sterilization forms an indispensable component of the safe use of small infant feeding containers. The implementation of appropriate sterilization techniques directly reduces the probability of bacterial contamination and subsequent health complications in infants. Ongoing adherence to recommended sterilization protocols is crucial for upholding infant health and promoting optimal feeding practices. The importance of thorough cleaning before sterilizing should also be emphasized to physically remove organic matter before applying any method to killing bacteria.

5. Infant Age

Infant age directly correlates with the appropriateness and effectiveness of small-volume feeding containers. These bottles, holding approximately 60 milliliters, are optimally suited for newborns and very young infants whose gastric capacity and feeding requirements are limited. The age of the infant dictates the volume of nourishment needed per feeding, impacting the utility of these smaller bottles. For example, a newborn may consume between 1 to 2 ounces (30-60ml) per feeding, making a 2-ounce bottle a suitable choice. However, as the infant grows, their nutritional demands increase, necessitating larger-volume bottles to accommodate their evolving needs. Continued use of a small feeding container beyond the initial months may result in more frequent feedings and potential frustration for both the infant and caregiver, if the age needs and demand.

The practical significance of understanding this relationship lies in avoiding overfeeding or underfeeding. Overfeeding can lead to regurgitation, discomfort, and potentially long-term weight management issues. Underfeeding can result in inadequate growth and development. By aligning the bottle size with the infant’s age and typical feeding volume, caregivers can ensure appropriate caloric intake. Consider the case of a three-month-old requiring 4 to 6 ounces per feeding; a 2-ounce bottle would necessitate multiple refills, disrupting the feeding process and potentially causing stress. Conversely, larger bottles may lead to wasted formula for newborns due to incomplete consumption, which may cause health problem.

In summary, infant age serves as a crucial determinant in the selection and utilization of small infant feeding containers. Careful consideration of the infant’s developmental stage and nutritional requirements ensures optimal feeding practices. Challenges persist in adapting feeding strategies to individual infant needs and growth patterns, necessitating continuous monitoring and adjustments to bottle size and feeding frequency as the infant matures. Failure to adapt, and a reliance on small feeding bottles longer than appropriate for the age of the child can lead to overfeeding or underfeeding or even potential health problems, underscoring the vital connection between infant age and appropriate feeding equipment.

Frequently Asked Questions

The following section addresses common inquiries regarding the use, care, and suitability of small-volume infant feeding containers, designed for infants.

Question 1: What is the recommended age range for utilizing small infant feeding bottles?

These receptacles are typically recommended for newborns and infants up to approximately three months of age, contingent upon individual feeding requirements and growth patterns.

Question 2: How frequently should small infant feeding containers be sterilized?

Containers should be sterilized before the initial use and regularly thereafter, particularly during the first few months of life, to minimize the risk of bacterial contamination. Consult manufacturer guidelines for specific recommendations.

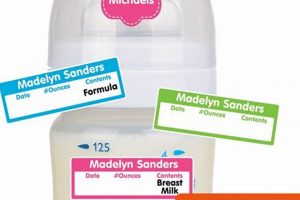

Question 3: Can small infant feeding containers be used for breast milk storage?

These containers are suitable for short-term breast milk storage, provided that proper hygiene and storage protocols are followed. Refer to established guidelines for safe breast milk handling and storage practices.

Question 4: What nipple flow rate is appropriate for small infant feeding bottles?

The nipple flow rate should be appropriate for the infant’s age and sucking ability. Observe the infant’s feeding behavior to determine the optimal flow rate. Consult with a healthcare professional for guidance if needed.

Question 5: What materials are considered safe for small infant feeding containers?

Safe materials include BPA-free plastics, glass, and stainless steel. Ensure that the chosen material complies with relevant safety standards and regulations.

Question 6: How should small infant feeding containers be cleaned?

Thoroughly clean the containers with warm, soapy water after each use. Utilize a bottle brush to remove any residue. Sterilize after cleaning to ensure optimal hygiene.

Understanding these answers promotes the safe and effective use of small feeding equipment. The principles outlined support improved infant safety and the use of this item.

The subsequent section will provide information on storing and traveling with this item.

2 oz baby bottles

The preceding discourse has illuminated the critical facets of small-volume infant feeding containers. From the imperative of portion control to the significance of material safety, the nuanced application of these implements demands informed decision-making. Nipple flow rate, sterilization methods, and the developmental stage of the infant emerge as paramount considerations in ensuring optimal nutritional delivery and minimizing potential health risks.

The responsible utilization of small infant feeding bottles extends beyond mere convenience; it embodies a commitment to infant well-being and fostering healthy developmental trajectories. Continued adherence to established guidelines, coupled with ongoing vigilance regarding product safety and individual infant needs, remains essential for maximizing the benefits and mitigating the risks associated with these specialized feeding tools.