The selection of infant feeding containers is a crucial decision for parents. These containers, designed for delivering nourishment to newborns and young children, are commonly manufactured from either a silicate-based transparent material or synthetic polymers. Understanding the properties of each material type is essential for informed decision-making.

The choice of material impacts several factors, including durability, potential for leaching of chemicals, ease of cleaning, and environmental impact. Historically, the silicate-based option was the standard. However, the advent of polymer manufacturing offered a lighter-weight, shatter-resistant alternative. Consideration of these characteristics is paramount for safeguarding infant health and well-being.

This article will explore the comparative advantages and disadvantages of each material type, examining aspects such as chemical safety, thermal resistance, cleaning protocols, and overall suitability for infant feeding. An objective assessment will empower parents to make a choice best aligned with their individual circumstances and priorities.

Practical Considerations for Selecting Infant Feeding Containers

Careful evaluation of the available options for infant feeding containers is essential. Several practical considerations can guide parents in making an informed choice.

Tip 1: Assess Material Safety: Scrutinize the composition of polymer-based containers to ensure they are free of Bisphenol A (BPA), phthalates, and other potentially harmful chemicals. Look for certifications indicating adherence to safety standards. Silicate-based options inherently lack these risks.

Tip 2: Evaluate Thermal Resistance: Consider the container’s ability to withstand temperature changes. Some polymers may degrade or release chemicals when exposed to high heat during sterilization. Silicate-based options generally exhibit superior thermal stability.

Tip 3: Prioritize Cleaning and Sterilization: Establish a rigorous cleaning and sterilization routine. Silicate-based containers are typically easier to clean thoroughly and are less prone to retaining odors or residue. Evaluate the cleaning requirements and limitations of different polymer types.

Tip 4: Analyze Durability and Shatter Resistance: Recognize the inherent fragility of silicate-based containers. While offering chemical inertness, they are susceptible to breakage. Polymer-based containers offer greater shatter resistance, mitigating the risk of injury from accidental drops.

Tip 5: Consider Weight and Handling: Evaluate the weight and ergonomics of each container type. Infants, as they begin to self-feed, may find lighter polymer-based containers easier to manage. Parents should consider their own comfort and dexterity when selecting container sizes and materials.

Tip 6: Evaluate Flow Rate and Nipple Design: Regardless of the container material, ensure the nipple design and flow rate are appropriate for the infant’s age and feeding abilities. A properly matched nipple minimizes the risk of choking or excessive air intake during feeding.

Prioritizing safety, durability, and ease of use ensures a positive feeding experience for both parent and infant. By carefully considering the characteristics of each material type, parents can make a choice that aligns with their individual needs and preferences.

The subsequent sections will provide a detailed comparison of the environmental impact associated with each container type.

1. Safety

The paramount concern in infant feeding revolves around safety, particularly regarding the potential for harmful chemicals to leach from the container into the infant’s formula or breast milk. Synthetic polymer-based containers present a variable risk profile due to the potential presence of compounds such as Bisphenol A (BPA), phthalates, and other plasticizers, which have been linked to adverse health effects, including endocrine disruption. While many manufacturers now produce BPA-free containers, the safety of replacement chemicals requires continued scrutiny. Silicate-based containers, composed of an inert material, eliminate the risk of chemical leaching, providing a chemically stable interface between the container and its contents. This inherent inertness reduces the potential for chemical contamination, representing a significant safety advantage.

Conversely, the shatter resistance of polymer-based options presents a safety advantage from a physical perspective. Fractured silicate-based containers pose a risk of cuts and injuries. Polymer-based containers, while potentially releasing microplastics upon degradation, are less likely to shatter into sharp fragments. The risk of physical injury necessitates careful handling and storage of silicate-based containers, particularly when infants begin self-feeding. Real-world instances of broken glass resulting in minor injuries highlight the importance of considering this factor. The safety evaluation must therefore encompass both chemical and physical hazards, weighing the risks associated with each material.

In summary, the safety aspect of infant feeding container selection requires a nuanced understanding of the potential risks associated with each material. While silicate-based containers mitigate chemical leaching risks, their fragility poses a physical hazard. Polymer-based containers, conversely, offer greater shatter resistance but may introduce the potential for chemical contamination depending on their composition. Informed decision-making necessitates a careful evaluation of these countervailing risks, guided by adherence to established safety standards and ongoing research into the long-term health effects of container materials.

2. Durability

The durability of infant feeding containers directly impacts their longevity and potential for safe, repeated use. Silicate-based containers, while inert, are susceptible to breakage from impacts or sudden temperature changes. Cracks, chips, or complete shattering render the container unusable and pose a potential hazard. Polymer-based containers, conversely, exhibit significantly greater shatter resistance. They are less likely to break under similar conditions, extending their lifespan. However, repeated sterilization or exposure to certain cleaning agents can degrade the polymer structure, leading to clouding, cracking, or leaching of chemicals over time. Therefore, while initially more durable in terms of impact resistance, polymer-based options may exhibit a shorter usable lifespan depending on usage patterns and cleaning protocols.

The practical significance of durability is multifaceted. Economically, more durable containers require less frequent replacement, reducing long-term costs. Environmentally, a longer lifespan translates to less waste generation. From a safety standpoint, compromised containers, regardless of material, pose a risk. Cracked or chipped silicate-based containers can harbor bacteria and present sharp edges. Degraded polymer-based containers may leach harmful chemicals. The choice between materials necessitates a careful consideration of these factors, balancing the risk of immediate breakage versus gradual degradation. For instance, a parent frequently traveling may prioritize the shatter resistance of polymer-based containers, while a parent primarily feeding at home may opt for the chemical inertness of silicate-based containers, accepting the risk of breakage.

In conclusion, the durability of infant feeding containers is a critical consideration influencing cost, environmental impact, and, most importantly, infant safety. Silicate-based containers are vulnerable to immediate breakage, while polymer-based containers may degrade over time with repeated use. The selection process should involve a comprehensive assessment of individual needs and usage patterns, prioritizing container integrity and adhering to recommended cleaning and sterilization guidelines to maximize the lifespan and safety of the chosen feeding solution. Adopting careful handling practices, such as avoiding sudden temperature changes with glass and selecting appropriate cleaning agents for plastic, can significantly enhance the longevity of both types of containers.

3. Cleanliness

Maintaining appropriate hygiene in infant feeding practices is paramount to prevent bacterial contamination and subsequent health complications. The selection of feeding container material silicate-based or polymer-based directly influences the ease and effectiveness of cleaning and sterilization protocols.

- Surface Porosity and Biofilm Formation

Silicate-based surfaces are inherently non-porous, minimizing the potential for bacterial adhesion and biofilm formation. Polymer-based materials, depending on their composition and surface treatment, can exhibit varying degrees of porosity, potentially harboring microorganisms even after cleaning. The microscopic texture of plastic surfaces can create niches where bacteria can colonize, making complete sterilization more challenging. Steam sterilization may be less effective on porous surfaces.

- Resistance to Cleaning Agents

Silicate-based containers exhibit robust resistance to a wide range of cleaning agents, including harsh detergents and sterilizing solutions. This allows for thorough cleaning without compromising the integrity of the material. Conversely, certain polymer-based materials can degrade or discolor upon exposure to aggressive cleaning agents, potentially leaching chemicals into the formula or breast milk. Manufacturers’ guidelines regarding appropriate cleaning agents must be strictly followed to prevent material degradation and potential health risks.

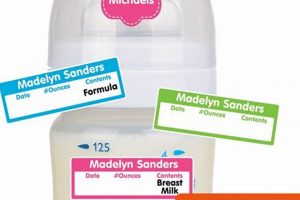

- Visual Inspection and Residue Detection

The transparency of silicate-based containers facilitates visual inspection for residual milk or formula, ensuring that cleaning has been thorough. Clouding or discoloration of polymer-based containers, especially after repeated use and sterilization, can hinder visual inspection, making it more difficult to detect residual contamination. Proper lighting and careful scrutiny are essential when cleaning polymer-based containers.

- Odor Retention and Flavor Transfer

Silicate-based materials are less prone to odor retention and flavor transfer compared to many polymer-based materials. Residual odors or flavors can indicate incomplete cleaning or bacterial contamination, potentially affecting the infant’s acceptance of subsequent feedings. Polymer-based containers may require more rigorous cleaning and rinsing protocols to prevent odor retention and maintain palatability.

The comparative ease of cleaning and sterilization associated with silicate-based containers offers a potential advantage in maintaining optimal hygiene in infant feeding. However, the proper cleaning and sterilization of any feeding container, regardless of material, is critical. Adherence to recommended cleaning protocols, regular inspection for damage or discoloration, and prompt replacement of compromised containers are essential practices for safeguarding infant health. The user must always comply with the manufacturers instructions for cleaning and sterilization.

4. Weight

The mass of infant feeding containers, or weight, is a significant factor influencing both caregiver convenience and infant usability. Silicate-based containers, due to the density of the material, inherently possess a greater weight compared to polymer-based alternatives of similar volume. This difference in weight impacts several aspects of the feeding process. Caregivers, particularly those with physical limitations, may find the heavier silicate-based options more challenging to handle during extended feeding sessions. Furthermore, as infants transition to self-feeding, the reduced weight of polymer-based containers facilitates easier grasping and manipulation, promoting independence and developing fine motor skills. A heavier container may lead to infant fatigue and frustration, potentially hindering the development of proper feeding techniques. Real-life observations in childcare settings demonstrate that younger infants often struggle with the weight of silicate-based containers, leading to spills and reduced intake.

The practical implications of weight extend beyond ease of handling. The increased weight of silicate-based containers contributes to higher shipping costs and a larger environmental footprint associated with transportation. Moreover, the choice of container material affects the overall weight of diaper bags and travel systems, potentially impacting caregiver mobility. Consider a parent regularly commuting with an infant; the cumulative weight of multiple silicate-based containers, combined with other essential items, can become a significant burden. Conversely, polymer-based containers offer a lighter alternative, reducing the overall weight load and enhancing portability. However, this advantage must be weighed against the potential concerns regarding chemical leaching and material degradation. Selecting a feeding container, therefore, requires a comprehensive assessment of the trade-offs between weight, safety, and durability, tailored to the specific needs and lifestyle of the caregiver and infant.

In summary, the weight differential between silicate-based and polymer-based infant feeding containers is a critical consideration with practical consequences for caregiver convenience, infant usability, and environmental impact. While silicate-based options offer chemical inertness, their increased weight can pose challenges for handling and transportation. Polymer-based containers provide a lighter alternative, facilitating self-feeding and reducing the overall weight burden, but require careful evaluation to ensure material safety. The optimal choice involves a balanced assessment of these factors, prioritizing both infant well-being and caregiver practicality. Understanding the weight implications of each material contributes to informed decision-making and promotes a positive feeding experience for both parent and child.

5. Sustainability

The concept of sustainability plays a pivotal role in evaluating the environmental impact associated with infant feeding containers. The selection between silicate-based and polymer-based options directly influences resource consumption, waste generation, and potential long-term ecological consequences. The production of silicate-based containers requires significant energy input for mining raw materials and high-temperature manufacturing processes. However, silicate-based material is inherently recyclable, with the potential for closed-loop recycling systems that minimize resource depletion. In contrast, the production of polymer-based containers relies on fossil fuels, contributing to greenhouse gas emissions and dependence on non-renewable resources. While some polymers are recyclable, the actual recycling rates remain significantly lower than those for silicate-based materials, leading to a greater accumulation of plastic waste in landfills and oceans. The environmental impact assessment must consider the entire life cycle of each material, from raw material extraction to end-of-life management.

Practical implications of sustainability considerations are far-reaching. Consumers increasingly demand transparency regarding the environmental footprint of products, influencing purchasing decisions. Manufacturers respond by adopting more sustainable practices, such as using recycled materials, reducing energy consumption, and implementing closed-loop recycling programs. Government regulations and extended producer responsibility schemes further incentivize sustainable practices in the packaging industry. For example, deposit refund systems for silicate-based beverage containers have proven effective in increasing recycling rates and reducing litter. Similarly, efforts to develop biodegradable or compostable polymers offer a potential pathway to mitigate the environmental impact of polymer-based infant feeding containers. However, the efficacy of these alternatives depends on the availability of appropriate composting infrastructure and the absence of harmful byproducts. The selection of a feeding container should align with broader sustainability goals, promoting responsible consumption and minimizing environmental harm. The carbon footprint of each choice becomes an important evaluation point for both companies and end consumers.

In conclusion, sustainability is an essential lens through which to evaluate infant feeding container options. Silicate-based containers offer advantages in terms of recyclability and the potential for closed-loop systems, while polymer-based containers pose challenges related to fossil fuel dependence and plastic waste generation. A comprehensive life cycle assessment, considering resource consumption, emissions, and end-of-life management, is crucial for informed decision-making. Consumers, manufacturers, and policymakers share a responsibility to promote sustainable practices in the infant feeding container industry, fostering a circular economy and minimizing the environmental burden on future generations. Challenges remain in improving recycling rates for polymers and developing truly sustainable alternative materials. Continued research and innovation are essential to achieve a more environmentally responsible approach to infant feeding.

Frequently Asked Questions

This section addresses common inquiries regarding the selection of infant feeding containers, focusing on critical considerations for safety, health, and practical usage.

Question 1: Is Bisphenol A (BPA) still a concern in polymer-based infant feeding containers?

While many manufacturers now offer BPA-free polymer-based containers, concerns remain regarding replacement chemicals. These alternatives, such as Bisphenol S (BPS), may possess similar endocrine-disrupting properties. Rigorous scrutiny of container composition and adherence to safety standards are essential.

Question 2: Do silicate-based feeding containers pose a significant risk of shattering?

Silicate-based containers are more susceptible to breakage than polymer-based alternatives. However, using protective sleeves and exercising caution during handling can minimize this risk. Inspecting containers regularly for cracks or chips is crucial to prevent potential injuries.

Question 3: How does sterilization impact the longevity of different container materials?

Repeated sterilization can degrade certain polymers, leading to clouding, cracking, or chemical leaching. Silicate-based containers generally withstand sterilization processes more effectively. Adhering to manufacturers’ recommendations for sterilization methods is essential to prolong container lifespan.

Question 4: Are there specific cleaning agents that should be avoided for polymer-based feeding containers?

Abrasive cleaning agents and harsh detergents can damage polymer surfaces, increasing the risk of chemical leaching and bacterial contamination. Mild, non-abrasive soaps are generally recommended. Always consult the manufacturer’s guidelines for appropriate cleaning products.

Question 5: Can silicate-based containers be safely heated in a microwave?

Sudden temperature changes can cause silicate-based containers to shatter. Gradual warming in a bottle warmer or placing the container in a bowl of warm water is generally safer. Always test the temperature of the contents before feeding the infant.

Question 6: What are the long-term environmental consequences of using polymer-based feeding containers?

The production and disposal of polymer-based containers contribute to fossil fuel consumption and plastic waste accumulation. While some polymers are recyclable, recycling rates remain low. Choosing reusable alternatives, such as silicate-based containers or exploring biodegradable options, can mitigate environmental impact.

In summary, selecting infant feeding containers necessitates careful consideration of material properties, safety standards, and environmental impact. Weighing the trade-offs between silicate-based and polymer-based options allows for informed decision-making that prioritizes infant health and well-being.

The following section provides a checklist for making an informed choice.

Concluding Remarks on Infant Feeding Container Selection

The preceding analysis has explored the multifaceted considerations surrounding infant feeding container selection, specifically addressing the trade-offs inherent in “glass bottles vs plastic bottles baby.” The discussion has encompassed chemical safety, durability, ease of cleaning, weight implications, and environmental sustainability. The objective has been to provide a comprehensive framework for informed decision-making, acknowledging the complexities and nuances associated with each material type.

Ultimately, the selection of a suitable infant feeding container requires careful deliberation and a nuanced understanding of individual circumstances. Prioritizing infant safety, adhering to established safety standards, and considering the long-term environmental consequences are paramount. Continued research and innovation are essential to further enhance the safety and sustainability of infant feeding solutions, ensuring the well-being of future generations.